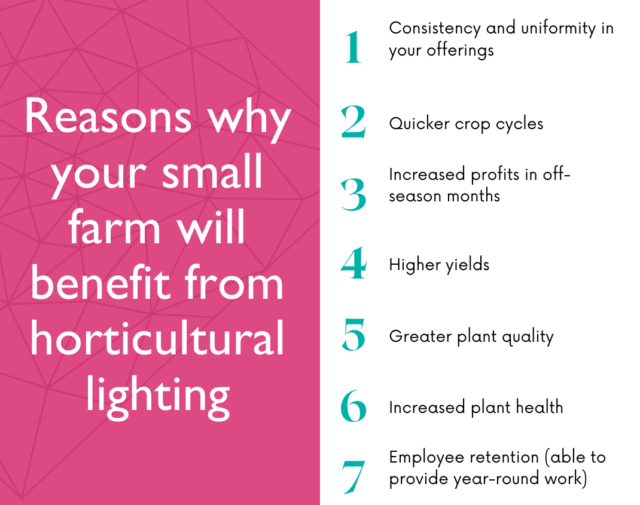

Whether you’re a grower wanting to extend your season in the hoop house or greenhouse, an urban rooftop farm, or a small indoor start-up—horticultural lighting gives you the flexibility and assurance that you will grow the highest quality products year-round.

With demand for locally grown produce increasing, it’s not surprising to see many small growers expand into off-season growing with horticultural lighting. Adding these systems helps create a more sustainable and profitable business model for many operations. So, let’s look at how lighting can help your small-scale farm operation, and which lighting options might be the best for your application.

What type of lighting is best?

Many small and medium-sized growers are already familiar with lighting such as T5 or T12 fluorescent tubes for seedlings and cuttings. While these can be a good low-cost option for early propagation cycles (when plants need low light levels), their light quality and intensity are not strong enough to produce good results as you transition into production phases. In addition, seedlings grown only under fluorescent light can stretch, be of poorer quality, and require more time to adjust to sunlight or higher light intensities—up to two weeks of adjustment and lost time—compared to those grown under high-quality horticultural luminaires. That’s because these lights are designed for people, not long-term plant growth.

So, what kind of lighting is best for production cycles? You need lights designed specifically for plant growth, such as horticultural LEDs or HIDs (high-intensity- discharge, typically high-pressure sodium, metal halide, or ceramic metal halide). The difference between fluorescent and professional grow lights is that grow lights have been built to deliver energy in the PAR (photosynthetically active radiation) spectrum. That means more energy is delivered to plants that can be used for photosynthesis. Professional horticultural lighting can also produce much higher intensities, which is important during dimmer times of the year when light intensity and photoperiods are low. Giving your plants the right type of light greatly improves plant health and productivity and can even be useful in helping control disorders such as Oedema, blossom end rot, and tip burn.

How to measure light

An important measurement of how much light you need is DLI (daily light integral in mol/m2/day), which is a function of light intensity and duration. DLI can be compared to how we measure cumulative rainfall over the course of the day. DLI changes throughout the year, with summer having high DLIs and winter having low DLIs. This is an important measurement for growers because maintaining a consistent DLI creates a uniform, high-yielding product year-round. For example, lettuce crops need 17 moles of light per day to maintain consistency and quality. In a northern climate like Ontario or Michigan, you will see an average DLI of around 5-7 moles per day—this means that lettuce is not receiving enough light to fully photosynthesize, thus reducing yields and increasing crop cycles. Adding supplemental light from LED or HPS luminaires to increase the DLI to an average of 17 moles of light will help keep yields and quality consistent.

Examples of small farms that have grown profits, yields, and plant quality with supplemental lighting

Let’s look at some smaller growers who use supplemental lighting to extend their growing season. One great example is Brooklyn Grange, a rooftop farm in NYC, which was able to extend its season into winter by growing greens under our HortiLED Top luminaires. The supplemental lighting helped bridge the fall and spring seasons for their locally grown greens and herbs, which they sell to grocery stores (through their CSA program) and restaurants. Another leafy greens grower is DeGoede Farms in Oregon. They also use the HortiLED Top luminaires to extend their season and keep their produce quality high and consistent for their customers.

LEDs can also be good for small-scale tomato/vine crop production. A customer in NYC used the HortiLED Top luminaires to grow tomatoes in a shipping container. This system was perfect because ceiling height was limited and lights needed to be placed close to the crop. Another example is Soulfood Greenhouse, a community non-profit greenhouse in Dallas, Texas, which successfully uses LED grow lights for tomato production to help feed families in their community.

Virgil Greenhouses grow specialty flowers such as Ranunculus. While traditionally a cool growing flower, seen in early spring or fall, the growers can keep their production consistent under the NXT2 HPS luminaires. Ranunculus generated high value per stem, so supplemental lighting was a natural choice to ensure the product was available year-round to customers.

What kind of horticultural lighting should I use for my setup?

The type of lighting you choose will vary by crop and application. However, below is a general overview of the lighting available. For more specific information, we have developed 4 crop cultivation guides with general guidelines on recommended light levels for the most popular crops including vine crops (cucumbers, tomatoes, peppers), leafy greens, ornamentals (cut flowers and bedding plants), and cannabis.

LED luminaires: If you are limited by electrical usage and want to save on energy costs, LEDs can be a great choice. Our DLC listed HortiLED Top 2.0, can also allow you to qualify for local rebate programs. Most LEDs offer red/blue or broad-spectrum outputs. For greenhouse applications, we typically recommend a red/blue spectrum because red and blue wavelengths are most efficient at converting photons into usable energy for photosynthesis. And since growers already receive full spectrum sunlight from outdoors, it makes sense to maximize the most efficient wavelengths. For indoor grows, a broad spectrum output, like that of our HortiLED Top 2.0 Daylight spectrum, is recommended because it produces a light that features wavelengths similar to sunlight (allowing the plant to take what it needs) and makes plant assessment easier. Since LEDs tend to have a more directional focus of illumination, they are great for spaced benches and tiered systems. LEDs can also be placed close to the crop surface without burning, making them great for leafy green and microgreen operations with limited space.

HPS (high-pressure sodium) luminaires: HPS lights can also be a great option for growers as the technology has successfully been used for decades to grow commercial crops. Newer models like our NXT2 and NXT-LP (designed for low ceilings) feature high-efficiency electronic ballasts and a spectrum ideal for production cycles of crops like tomatoes, cucumbers, ornamentals, and cannabis (flowering). The radiant heat is also great for off-setting heating costs for northern growers. Also, the wider, more diffuse distribution of HPS luminaires means you need fewer luminaires to achieve uniform light distribution compared to LEDs—making them a more budget-friendly option.

CMH (ceramic metal halide) luminaires: CMH luminaires, like our NXT-LP CMH, are another type of HID light that emits a stable, broad-spectrum light ideal for greens’ operations and early vegetative growing phases—especially for applications that are indoor with limited or no sunlight. Growers such as Aqua Greens, who grow greens and herbs indoors in a tiered system, use CMH luminaires. They love that lights can be placed close to the canopy without burning while emitting a white light that makes it easy to assess plant health.

What should I look for in a lighting system?

Always ensure your luminaires are safety certified by a recognized organization such as UL or CSA. If you choose LEDs, another thing to look for is if the product is DLC certified, which can help you receive rebates off your project costs through local energy incentive programs. You should also check that the company has a history of working with horticultural crops, so they understand your goals and the challenges you may face. Many new lighting companies have entered the market with little experience working with growers. Working with a North American-based lighting manufacturer that offers local service and support can also make a big difference in ensuring your investment is protected.

How many luminaires will I need for my crops?

The amount of lights you need to install will depend on your application and the type of lighting you choose. In general, HID lighting, because of its reflector technology, will require fewer luminaires than LEDs. For greenhouses, you will naturally require less lighting than if you grow in a sole source (indoor) warehouse without any natural light. Working with a reputable lighting company is key, as they will create a custom light plan designed specifically for your application, which will show you the best possible coordinates of each luminaire for plant growth.

How much light intensity will I need?

The light intensity needed for each crop will vary by species. In general, leafy greens require lower light intensities, while fruiting crops, like tomatoes and cucumbers, need higher intensities. Ornamentals can vary, but usually need medium to high light intensities to grow high-quality crops. Cannabis is a high-light crop and needs a high light intensity for high yields. We calculate recommended light levels using PPFD (Photosynthetic Photon Flux Density) and DLI. Most growers will use DLI as a starting point, and it has become an important tool for managing the light environment to optimize crop growth. For example, an optimum DLI for leafy greens is about 17 mol/day, while tomato and vine crops would need about 25-30 mol/day.

Conclusion

Lighting can seem like a big upfront cost, but the rewards are well worth it if you want to ensure a steady profit and consistent crop yields. Supplemental lighting in a hoop house or greenhouse to extend your season is a great way to make extra money on quick crops like lettuces and microgreens, get an early start on high-value fruiting or flowering crops, or provide year-round offerings on high-value ornamentals and produce. As daylight becomes shorter in the winter, this can delay crop cycles by up to two to four weeks, depending on the crop. Just imagine all the extra profits you could be making with the addition of lighting. Remember, you don’t need a big setup to be a profitable year–round farm—just the right equipment. Get started today by contacting your local sales managers to see what lighting can do for you!