Let’s discuss the importance of your often forgotten and yes, sometimes neglected (luminaire) grow light reflector.

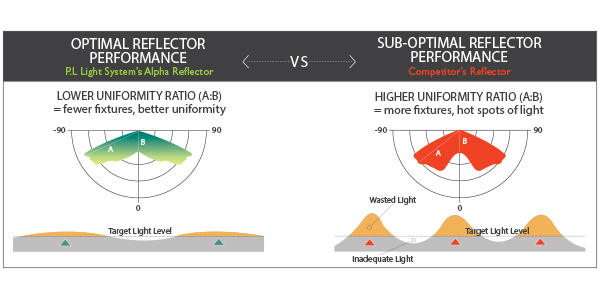

When we are looking at High Intensity Discharge (HID) lighting like HPS, the purpose of a grow light reflector is to efficiently get that light down into your crop—while spreading that light evenly or uniformly over the crop. Uniformity is critical for the health of your crop and to generate consistent growth and yield. The right grow light reflector will increase your light output. Maximize your uniformity and reduce the number of light fixtures you require to achieve your light levels and crop quality.

Crop Health & Yield…

How can uniformity affect the health of your crop and yield? Simply, an evenly lit crop will consume all inputs such as nutrients, water, CO2 etc. equally. Alternatively, an unevenly lit crop will have darker areas that will be over watered and over fertilized if you are meeting the higher lit crop areas’ needs. The lower lit areas will also have a lower rate of photosynthesis due to the lower light intensity creating less growth. This will have an impact on your crop and your pocketbook.

Surfaces

Reflector patterns, materials and shapes really affect the dispersion of light and how it is distributed out of the grow light reflector. Basic Physics….Flat surfaces do not reflect as efficiently as a curved surface in a reflector. White is a reflective medium, but it is not as reflective as a shiny aluminum type surface. A dimpled texture vs. a smooth surface will also diffuse the light and provide more coverage. So, when you are looking at a grow light reflector, ensure that you are getting maximum reflectivity from a shiny, curved and dimple textured surface . PL’s grow light reflector has a highly reflective finish which provides diffusion. It also provides a corrosion resistant surface and a low sensitivity to pollution. Keeping your grow light reflector clean is another topic we will address in an upcoming maintenance blog. A dirty grow light reflector will not reflect to its optimal capability.

Different Shapes…

I’m going to say bigger is not always better, and that’s not something you often hear. But in this case with reflectors, it’s true. So, you may see very large footprint reflectors that appear to be covering a huge area – and they are. But not efficiently or uniformly. The further light travels out before it reflects down, the more it diminishes, and that’s not what you want for your crop.

If you measure the light directly under the large hood at the crop, you will see – as we see in many grows – that the output may be for example 800µmol/m2.s1 (micromoles per meter squared per second), but when you go to the perimeter of that grow light reflector, that light level can drop down to 400 µmol/m2.s1 or less. That is not giving you the uniformity or light level your crop needs. A reflector has to give you a consistent uniformity over the entire crop canopy. That is what it is there for. A smaller oval shaped reflector causes the light to travel a very short distance before being reflected down maximizing the light output. High quality surfaces and textures can give the same coverage as a large hood but with the desired uniformity.

Distribution Patterns

Different shapes will direct the light to your crop in different patterns. Determining your grow light reflector needs can be affected by the amount of height you have available between the crop canopy and the base of your mounted light. When you don’t have a lot of mounting height, there are reflectors engineered to have a broader spread pattern to cover more of the canopy at a closer distance such as the PL Alpha or Delta reflectors. Alternatively, if you are fortunate to have a lot of mounting height, there are reflectors that have a narrow reflection angle to drive the light down into the crop while keeping uniformity optimized such as the Beta and Zeta. This is extremely valuable for tall crops where light doesn’t penetrate well into the lower leaf areas.

I also recommend that you pay attention to the edges of your crop area. There are two scenarios, 1) Light will drop off at the edges of the crop area due to less accumulated light from fewer fixtures 2) Additional lights are added to keep the light level up on the edges. But a considerable amount of light loss occurs to non-crop areas or walkways. There are different types of reflectors that can help you with this too. PL Light has an Asymmetric reflector that basically draws a line and directs the light back onto your crop at an edge, keeping the edge lit to the light levels that you need, matching the rest of the crop while not allowing that light to spill into non-crop areas preventing a waste of light.

LED (Light Emitting Diode)

Another type of lighting is LED luminaires that have a lens and optics integrated into the fixture. PL Light Systems has a full lineup of HortiLED lights to suit your needs. HortiLED TOP light, HortiLED MULTI light (which is used for multi layers), as well as HortiLED INTER canopy. The optics in the TOP and MULTI luminaires deliver either an 80-degree distribution angle for a deeper canopy distribution pattern. Or a 150-degree distribution angle for a broader spread (similar to the Alpha reflector we use in our HPS fixtures). The INTER has an integrated reflector that actually internally reflects and laterally refocuses the light through a lens. It gives a perfectly symmetrical distribution across the top of the leaves. Focusing the light on top of the leaves is important because the leaves absorb the majority of the light from their top surface.

Light Plans

PL Light Systems can provide you with customized light plans using the best reflector for your needs and showing you the optimum fixture spacing with maximized uniformity.

Last Reflection

Reflectors play an important role and should be considered equally when looking at a lighting investment. Depending on the layout you have and the mounting height available, there are many reflector options out there. You now know their importance and what features to compare to achieve the optimum light levels and uniformity.

Happy Growing!

Written by – Christine Stein is the Regional Sales Manager of Central & Western Canada. Christine brings years of industry experience and passion to each of her projects, continuing to deliver results to growers. Contact Christine.