With so many new LED luminaires being introduced into the market, we have seen trends shift toward vertical growing. A big reason for this is that LEDs can be more energy/space efficient and do not produce the same radiant heat as traditional HID (high-intensity discharge) technology. Therefore, your light source can be placed closer to your crop. Having the light source close to the crop canopy enables growers to maximize space and grow upwards on vertical tiered racking systems. Since this style of growing can be done almost anywhere, we see many taking advantage of underutilized urban indoor spaces such as warehouses and other commercial buildings.

In this article, we will overview the pros and cons of growing vertically in terms of cannabis production and the things a grower should consider before investing in a vertical system vs. a traditional CEA setup. Let’s first take a quick look at the differences between a vertical farm and a traditional single-tiered indoor farm.

Vertical Farm (aka Plant Factory)

- Vertical multi-tiered surfaces to maximize crop yield in a smaller footprint

- Generally, crops are grown in non-traditional buildings, such as shipping containers or repurposed warehouses. Sometimes, greenhouses can also be used

- Plant factories tend to be located in more urban settings

- The use of a fully controlled environment, including temperature, sole-source lighting (LED mainly), humidity, irrigation, fertigation, and CO2

Controlled Environment Agriculture (CEA)

- Indoor farming in either a greenhouse or indoor facility, single layer, or vertical high-wire

- The use of a fully controlled environment, including temperature, supplemental or sole-source lighting (HID or LED), humidity, irrigation, fertigation, and CO2

- Mainly located in rural or peri-rural settings, or, in some cases, urban rooftops

As we can see, there are many similarities between growing vertically and in a traditional single-tiered application, with the biggest difference being the ability to maximize space in multi-tiered racking systems.

Growing Cannabis in a vertical, multi-tiered system

Better use of space is the #1 reason we hear from growers contemplating the move to a vertical racking system – especially in the cannabis market. Something we used to hear all the time is, “If I can remove all of the heat from 1000W HPS luminaires from my indoor space and utilize that four-foot distance, then I could double my growing canopy within the same footprint and therefore double my production”. Is this a true statement though?

This is true for low-growing crops like leafy greens and herbs because these crops tend to require a much lower light level for growing. These crops do not produce “fruit” within a canopy, so you can grow them in very tight proximity with racks being 12-18 inches apart vertically. In this way, you can double, triple, or quadruple your growing space with low-output LED lighting along the lines of our HortiLED Top 2.0. This type of setup also works well for cannabis propagation when the plants are small and light requirements are low, typically between 90 and 250 μmol/m2/s1.

Once cannabis plants enter the veg and flowering stages, however, it becomes a bit trickier as you are growing a larger, bushier crop rather than a low-growing crop like lettuce. A cannabis grower used to growing a large bush that produces a massive amount of bud may now find themselves rethinking how they grow. As we see with many who are growing vertically, they now must grow a smaller plant to compensate for the rack height and, therefore, may not produce as much yield per plant as they are used to. This may even lead growers to decide which cultivars will be best suited for growing vertically, as some cultivars are naturally shorter and have fewer leaves, which will serve better in a vertical operation.

COSTS TO GO VERTICAL

The question becomes, “If I double my canopy, but produce less bud per canopy square foot, am I going to be more profitable or not?” – This is a hard one to answer. If you were to double your canopy size in one room but produce 25% less per square foot of canopy, would you still be profitable?

Let’s do the math on this:

If you currently produce 40g/sq. ft and have 1000 sq. ft of canopy space, then you produce 40,000 grams or 40 kilograms per 1000 sq. ft. If you double the canopy in this room but produce 25% less per square foot, then you will produce 30 kilos per 1000 sq. ft―so 60 kilos per room when the canopy is doubled. That seems like a great increase, as your overall production just rose by 50%! But does this make you more profitable?

Let’s now look at power consumption. If you are switching to LEDs from HPS to grow vertically, then you may also be thinking of the potential electrical savings. Currently, the most common replacement for a 1000W HPS is a 600W LED. That is a savings of 40% for power, but since you need to double the lighting in your space for two tiers of vertical grow, this works out to be around 20% more wattage in your room (at minimum). The question to think about becomes – do you have enough power available? And does the 20% increase in power consumption eat up a large portion of the 50% increase in production?

WATTS AND BTUs

Another aspect to consider is the direct correlation between watts and BTUs (for more on this, check out our blog on HPS or LED for cannabis). The 20% increase in watts is also a 20% increase in cooling, so you should also be thinking about whether you have the cooling capacity in your current setup or what will that cost be in a new grow installation.

When we calculate the load for heating/cooling equipment, we use a measurement of energy called British Thermal Units (BTUs). A BTU is equal to the amount of energy used to raise the temperature of one pound of water one degree Fahrenheit.

When factoring in the heat given off by a luminaire, the BTUs are calculated off the total wattage of the light.

A single watt of power is equal to 3.41 BTUs, so a 600W luminaire will produce 2,046 BTUs and a 1000W will produce 3,140 BTUs – irrespective of whether it’s HID or LED.

So, the 20% increase in watts in our previous scenario equates to a 20% increase in cooling, so you should also be thinking about whether you have the cooling capacity in your current setup or what will that cost be in a new grow installation.

20% ↑ watts = 20% ↑ cooling requirements

- Does the facility have the power & cooling capacity to manage the increase

- How will this increase 20% A/C requirement reduce your 50% increase in production/revenue

The question to think about becomes do you have enough power available? And does the 20% increase in power consumption eat up a large portion of the 50% increase in production?

Let’s look at an example:

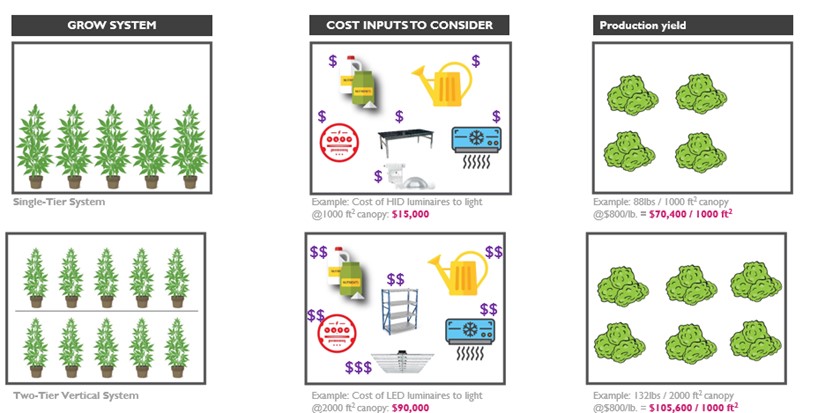

Say you’re selling your bud for $800 per pound and producing 88 lbs. per 1000 sq. ft of the canopy (40 kg) (thus making $70,400 for every 1000 sq. ft). After switching to a tiered system producing 50% more, you will make $105,600 per 1000 sq. ft.

With this math, you will need two full years of production to recoup just the added cost of lights alone. If you were to compare this 1000 sq. ft of indoor space to that of a greenhouse, the cost difference becomes greater, since the greenhouse will use less artificial light because of the free natural sunlight from outside.

Why 50% increase and not 100%?

You may ask yourself why you would not produce 100% more product by doubling your canopy square feet. This is a valid question. The reason is more than just a smaller plant that produces less bud as stated above.

This 50% number has been thrown around for a few years now, like in this article. They probably did increase production by 157% as stated, but this article can be deceiving in some of the benefits it claims. Yes, there was a decrease of 40% of power per luminaire, but then doubling the lighting in the room is still an increase of 20% of watts and BTUs in the space. They also state they reduced HVAC by 35% per sq. ft of canopy, but this is still an increase of 30% in the same room since the canopy is doubled. And while the decreased cycle time of 25% looks appealing, it comes at the cost of 25% less production per canopy sq. ft. The statistic that pops out the most is the claim that the cost to produce per pound was reduced by 75%. This is obviously hard to quantify as we do not know what this data is being compared to. Looking at the capital costs laid out above, if this is measured against a standard grow room using HID luminaires, then it may be hard to believe this number– but since we do not know what the comparable is, we cannot quantify it.

LIGHT UNIFORMITY AND CANOPY PENETRATION

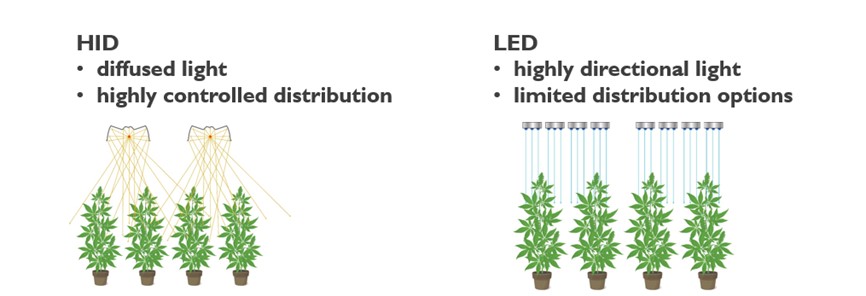

How the light penetrates the crop canopy is a big consideration when comparing HID and LED technologies. There is no easy math to calculate an ROI for this, but when comparing light plans from one source of light to another, be sure to consider the distance of the light source from the canopy.

There is a big misconception in the industry that the ability to have your LED lights closer to your crop will help increase production lower into the crop. However, in this case, the shadows created by the top layer of leaves are much bigger than if the light was further away. Also, light penetration into the crop comes from the crossover between fixtures. This is easily accomplished by HPS luminaires that use reflectors to diffuse light, uniformly delivering a much wider range of illumination deep into the canopy at further distances away. In contrast, LED luminaires need to be spaced more closely together to achieve higher uniformity over the crop canopy.

LUMINAIRE COSTS

The cost of the luminaires you purchase should also come into consideration. A crop like cannabis is a high-light-level crop, so you need to use an LED that can deliver equivalent light levels of an HID. The current market is that per µmol delivered to the crop, LED lighting can be 3-4 times more expensive than HPS. If you spent $15,000 to light 1000 sq. ft of canopy with HPS, you would need to spend at least $90,000 on LEDs to light the 2000 sq. ft of tiered grow space. When you combine this with the additional costs of racking, fertigation, etc., the increase in production starts to lose its value quickly.

ENVIRONMENTAL FACTORS TO CONSIDER

Besides lighting, the environmental conditions in a vertical grow can be quite complex. The cannabis plant needs good airflow―enough to create movement of the branches to grow a sturdy, healthy plant. When growing vertically, keeping good air movement around your crop is harder. With this comes more complications from small microclimates that can form within the same room. This can cause differing temperature, humidity, and CO2 levels within the same space.

Most growers who have switched to a multi-tier system have also had to add more extensive sensors and controllers to help offset these issues, hiking the costs of the operation. As with lighting costs, these factors are increased even more when comparing an indoor multi-tier grow to a greenhouse. A professional greenhouse grower understands that the taller the greenhouse with more open air space above the crop, the more stable and easier to control the environment than in a small space. This is because the slightest change in HVAC, humidity, or CO2 in a small space changes the overall environment much faster than in a larger greenhouse. This can be very challenging for the indoor grower to monitor and control. Think of it like comparing a bathtub full of water to a pool. One gallon of hot water will noticeably change the temperature of a tub of water but may not be noticed at all in a pool full of water.

CONCLUSION

In conclusion, vertical growing could be a great resource for feeding an ever-growing population by utilizing indoor spaces more efficiently for space-efficient crops like greens. While we’ve seen a boom in bringing this technology into the cannabis market, we are also seeing many cannabis growers move away from this. On a recent trip to southern California, we toured many traditional cannabis indoor grows within the L.A. area that all talked about removing their HID lighting and switching to a vertical grow system with LEDs. We also toured many vertical operations that have been in business for a while. They explained that, with the current downward trend in wholesale pricing, they are looking to get out of their indoor operation to move east toward Desert Hot Springs and Palm Springs to build a desert greenhouse to utilize the power of the sun while still being near their customers.