How LED and HPS Lighting can affect air and leaf temperature: The Effects of Convective Heat vs. Radiant Heat

As growers are educating themselves more on different lighting technologies, we have been faced with questions about what effects different light sources have on temperature and crop production and what the difference is between Convection Heat and Radiant Heat.

Anyone remotely familiar with HPS (high-pressure sodium) and LED lighting understands that you need to maintain a certain distance from your crop to the hot HPS while cooler LEDs can be mounted closer to the canopy. Both of these lighting applications have their pros and cons depending on the crop you are growing.

We also know that LEDs can lower indoor cooling costs while HPS lamps can lower heating costs (especially for those in Northern climates). However, there is a common misconception when calculating efficiencies. When we calculate the load for heating/cooling equipment, we use a measurement of energy called British Thermal Units (BTUs). A BTU equals the amount of energy used to raise the temperature of one pound of water one degree Fahrenheit. When factoring in the heat given off by a luminaire, the BTUs are calculated on the total wattage. If you have a 600-watt HPS lamp, the BTUs are the same as a 600-watt LED. A single watt of power is equal to 3.41 BTUs, so a 600W luminaire will produce 2,046 BTUs. This is true for both the LED and the HPS grow lights.

If they both produce the same number of BTUs, then where is the savings in cooling an LED over an HPS?

LEDs have now surpassed HPS in their efficiencies, with some delivering over three micromoles of light per joule (Joule is a measurement of watts – one joule = one watt) while the HPS is closer to two micromoles per joule. So, it will take less than 600W LEDs to reach the same light level produced by the HPS.

If both technologies produce the same number of BTUs per watt, why does it feel so much warmer under the HPS than the LEDs? Why can I mount my 600W LED closer to the crop than the 600W HPS?

The difference here is solely based on how these technologies differ in dissipating heat produced by the amount of energy put into the luminaire. For this, we need to explain the difference between Convection and Radiant heat.

One of the biggest differences between LEDs and HPS is radiant heat. There are three different methods of heat transfer: Conduction, Convection, and Radiant Heat. Conduction is the physical transfer of heat from one object touching another. Because lights for growing are typically hanging, this does not come into play in a growing operation (it is used in the form of a heatsink within the luminaire, which is the thermal path heat energy released from inside the light to the outside – more about this later). Convection is the transfer of heat energy from the heat source to the surrounding air, resulting in the heat rising into the cooler surrounding air. Radiant Heat, however, is the transfer of energy via electromagnetic radiation or infrared wavelengths. The infrared wavelength can be directed toward a target with a reflector.

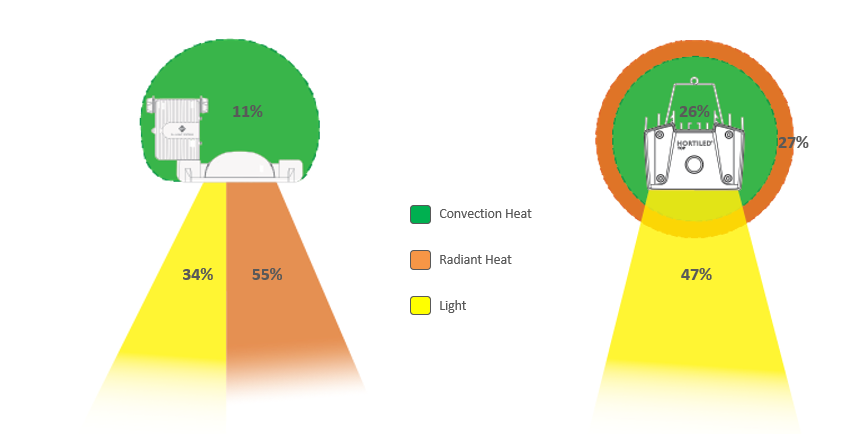

Using the example above with the 600W luminaires, an HPS will dissipate approximately 55% of the 2,046 BTUs as radiant heat directed toward the crop by the reflector, while the LED will be as low as 27% as radiant heat. Also, the HPS will deliver approximately 34% of that energy in the visible light wavelength. The LED will produce 40-50% of its BTU energy as visible light (and this is why the LED is more efficient). Vice versa, the HPS luminaire only transfers approximately 11% of its total BTUs in the form of convection heat, while the LED will have 25-30% of its total BTUs dissipating through convection.

| HID | LED |

| Produces a significant amount of radiant heat (55%) | Produces minimal radiant heat (27%) |

| Can cause crop burn if mounted too close to canopy | Can be mounted close to crop canopy |

| HID technology is more effective in transferring heat to crop canopy | Leaf temperatures are approx. 34.3F (1.3 C) lower in a sole source LED application vs. HID |

| Radiant heat from lights offsets cost of heating with natural gas/electricity in supplemental lighting applications | Minimal radiant heat reduces cooling costs in sole source lighting applications |

The reason for the differences in heat transfer is that the primary heat source of the HPS is in the lamp, with a reflector directing its radiant heat downward. The LED, however, produces heat within the device itself. Due to the inefficiencies of the semiconductor processes that generate light from the diodes, close to 60% of the input power is lost to heat.

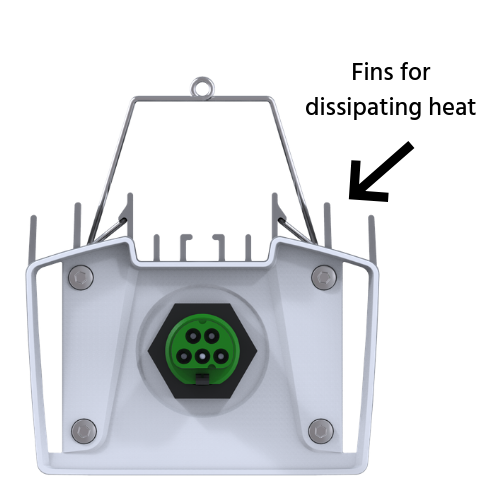

With the high-powered LEDs being used as grow lights, it is essential to remove this heat through thermal management (heatsink). Without good heat sinking, the internal temperature of LEDs rises, causing the output of the diodes to change. Most LEDs are measured for performance in a lab where their temperature is maintained in an optimal range – typically 25 degrees C. However, if that temperature increases beyond that, there is a direct correlation between failures and lower output of light per watt. (note that while this is true with almost all lighting technologies, a much higher temperature must be reached before failure rates increase with HPS). Heatsinking can be done in a passive process by conduction, which moves the heat away from the diodes and circuit board and utilizes more surface area in contact with the surrounding air (like you will see with the fins on the top of the PL Light HortiLED Top Light).

Another consideration with LEDs that can affect the amount of heat generated is the spectrum. A red/blue spectrum is more efficient than a full spectrum or white LED. The same luminaires with different spectrums will pull the same amount of watts, but the full and white spectrums will deliver less overall light. It will take more total lights of a full spectrum LED to achieve the same light level as red/blue alternatives. More luminaires in a grow room will be more BTUs as well.

Some lesser horticultural grow lights will use convection heat within the luminaire by utilizing fans or implementing a liquid cooling system. This is done because the high thermal conductive materials used for passive cooling tend to drive the overall price of the luminaire higher. (Fans and liquid-cooled lamps present another world of problems that we can touch on in another post)

What are the pros and cons of radiant heat for my grow?

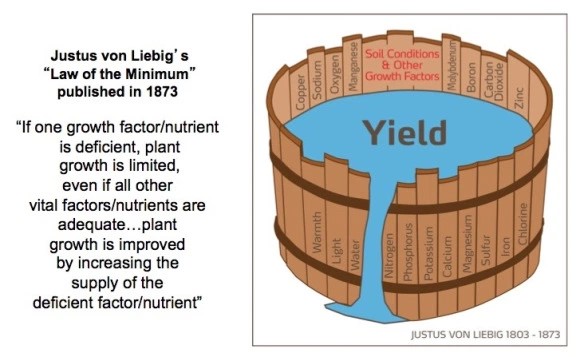

Now that we understand the differences in how these two technologies dissipate the same amount of energy, let’s discuss how they can affect our grow. To do this, we need to understand Liebig’s Law of Limiting Factors stating that growth is dictated NOT by total resources available, but by the scarcest resource.

This can be demonstrated when we add supplemental lighting to a growing operation and then need to increase the CO2 levels to maximize the use of light. The same will be true with heat since temperature is the second most important environmental parameter for growth after light. Temperature affects many physiological processes from photosynthesis, respiration, transpiration, uptake of nutrients, cell division, and cell elongation. It also manipulates developmental processes like cultivation period and seed germination. There is also a direct relationship between temperature and relative humidity.

As temperature is increased, the photosynthesis rate will double for every 10 degrees Celsius until the optimal temperature is reached. One can therefore draw a direct correlation between temperature and plant development rate since higher temperatures increase cell division. Higher temperatures will also help speed up many processes, such as the unfolding of flowers and leaves. But as the law of limiting factors suggests, eventually too high a temperature will be limited by another factor that could damage the plant and hinder growth.

Measuring leaf surface temperature (different from air temperature) is important in controlled environment agriculture. Light levels and CO2 in a growing operation can always be increased but if leaf surface temperature is too low then photosynthesis will be limited. This is where the difference between radiant heat and convection heat from your light source comes into play. Since convection heat is energy dissipated into the surrounding air, then a light source with a high convection rate (LEDs) will affect ambient air temperature in your grow while a light source with high radiant heat (HPS) will affect leaf surface temperature in the direction of the reflector.

Measuring the temperature in your grow is not the same as measuring leaf surface temperature. Just like your thermostat in your living room may read 69 degrees Fahrenheit, your body is maintaining a temperature of 98 degrees Fahrenheit; much is the same for plants. Taking true leaf temperature is like putting a thermometer under your tongue. Leaves can control plant temperature through respiration and transpiration, which occurs in open pores on the leaf called stomata. The stomata can absorb heat from the ambient air and radiant heat on the leaf surface before releasing moisture to cool the plant if it gets too hot (like your body can sweat). Leaf temperature is almost always different from the ambient air temperature. Because most biological reactions and metabolism of plants occur in the leaf, knowing how leaf temperature is affected by your lighting systems is important. Most of these reactions only operate within a certain range and are optimized in a very narrow temperature range.

The bottom line: If you are growing a plant that performs better with a higher leaf surface temperature then you may want to factor in radiant heat when trying to decide on your light source, as this is the second most important limiting factor in your grow!

Written by – Eric Moody, Sales Manager – The Americas, works with growers at all stages of grower. Eric works with growers in traditional horticulture as well as medicinal and recreational legal cannabis to help them increase yield through supplemental lighting.