In the rapidly evolving landscape of controlled environment agriculture (CEA), dynamically tunable LED lighting is emerging as one of the leading technological innovations. These advanced lighting systems enable precise, real-time adjustment of the light spectrum and intensity in response to the plants’ needs, natural light levels and even, in some instances, demand on the electrical grid. While the potential benefits of this new lighting technology cannot be denied, there are also some potential drawbacks and/or challenges that should be considered. This article delves into both the pros and cons of multi-channel tunable LED lighting to help you decide whether it makes sense for you to implement in your commercial growing operation.

Customizable Light Recipes

Tunable LEDs enable precise control over the light spectrum, allowing growers to tailor lighting conditions to the specific requirements of various plant species and developmental stages. So, with dynamically tunable light fixtures, on-demand spectral customization can be used to enhance photosynthesis, improve plant morphology, and potentially increase yields.

This “tunable” feature of dynamically tunable LEDs could be great for growers in a highly competitive and/or specialty crop market where the ability to dial into the optimal spectral recipe for a specific cultivar can result in crop quality and/or productivity improvements that distinguish them from the competition.

In other cases, growers may wish to “futureproof” their grow environment to allow for different crop types they may choose to grow in the future—based on the shifting profitability of certain crops or other unforeseen impacts, such as crop virus outbreaks.

Although growers typically think of a (4-channel) fixture that can deliver a fully-tunable spectrum when they hear “dynamic spectrum”, it should be noted that there are also 2- or 3-channel LED products available which offer growers a broad, efficient spectrum on the main channel that can be used for the majority of the lighting schedule, but with 1- or 2- additional channels that allow for limited applications of other wavelengths as and when they are needed.

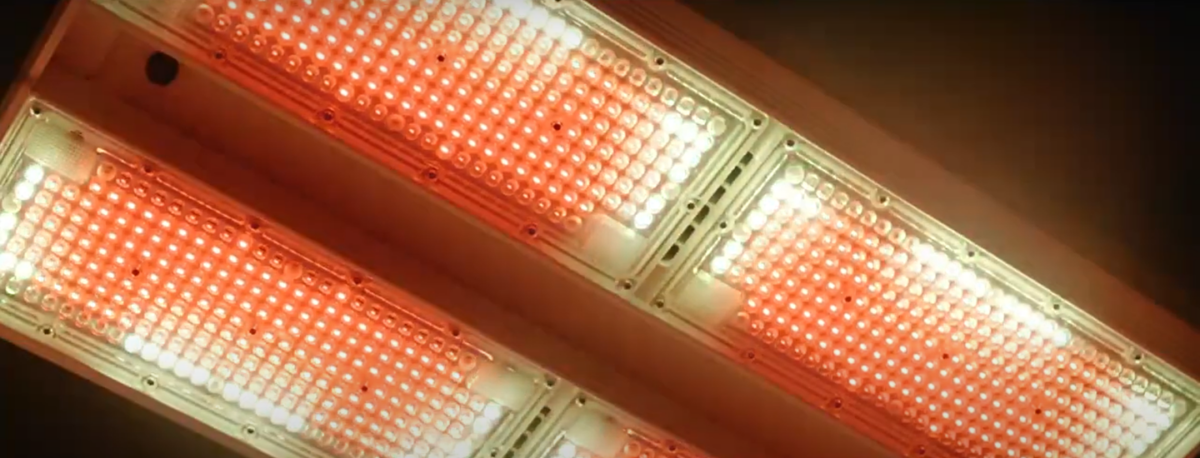

For example, the ParFX Ultra 2-Channel fixture has a recipe of 90% Red : 5% White : 5% Blue on the main channel with a second Far-Red channel. Studies have shown that specific applications of Far-Red light can be very beneficial. For a chrysanthemum grower for instance, having the ability to apply a dose of far-red light as and when needed could be great since studies have shown that stem elongation in chrysanthemums can be controlled by applying low-intensity far-red light for half an hour at the end of the day to deliver longer flowering shoots (Wageningen University & Research, 2023). Similarly, far-red light has been shown to produce larger leaves for cucumbers and peppers—minimizing fruit stacking or, in the case of strawberries—creating a more open canopy that allows for more light to reach the fruit and easier harvesting.

Conversely, the application of blue light* can be used as a growth regulator to suppresses growth extension, which can be advantageous when height requirements are a factor or when plants need to be more compact in size. Blue light receptors may also play a role in the production of carotenoid and anthocyanin development. This can be seen in leaf colouration, such as enhancing the colour of red lettuce varieties or increased pigment and nutrition in peppers (Naznin et al., 2019).

Determining the optimal light spectrum for each crop and growth stage, however, requires extensive knowledge and experimentation. The interactions between light spectra and plant responses can be complex, and missteps could lead to sub-optimal growth and/or decreases in yield.

So, although the idea of being able to adjust and “experiment” with your grow lighting is undeniably exciting and can serve as a valuable tool for some, the reality is that for commercial growers, consistency and predictability are key. For growers subject to supply contracts with grocery chains / garden centers, their main focus is going to be on ensuring consistent quality and yield in order to deliver on those contracts. In which case, they would likely prefer to eliminate as many variables as possible. Since changes in light intensity and spectrum can affect not only other inputs like nutrient uptake and VPD, but also the plant morphology, growers are advised to initially set up a trial area to see how their crops perform under various spectral recipes to avoid potentially compromising one or more harvest cycles across their entire crop.

For those growers who don’t want to spend time on trying to figure out the optimal light spectrum (and necessary adjustments to other inputs) for each specific crop and/or cultivar—a fixed spectrum (optimized to accommodate multiple crop types and growth stages) might make more sense.

Maintaining Optimal Light Intensity

For years growers have used the “1% light intensity rule”, which states that a 1% increase (or decrease) in light intensity results in a corresponding 1% increase (or decrease) in yields—up to a saturation point (Marcelis et al. 2006).

Many researchers, including Dr. Erik Runkle and Dr. Bruce Bugbee also agree that in CEA applications where high light intensities are required, the light quantity (intensity) generally has a stronger and more consistent impact on crop yield than light quality (spectrum).

So, although growers are aware of the relationship between light intensity and yield, they may not realize that, when it comes to dynamically tunable LED lighting, the amount of light (PPF) produced by any tunable light fixture will fluctuate based on the spectral recipe dialed into. For example, with P.L. Light Systems’ 4-Channel ParFX Ultra Max tunable LED product, if the spectrum is tuned to a recipe of 95% Red : 5% Blue, the fixture will output 4530 μmol/s of light. If the spectrum is tuned to a recipe of 76% Red : 6% White : 8% Blue : 10% Far-red, the fixture will output 4130 μmol/s of light. That’s a difference of around 9% and by the 1% intensity rule, this would reduce yield by up to 9% as well.

So, spectral tuning needs to be carefully balanced with the maintenance of adequate light intensity. As a grower, you need to weigh the economic benefits of the potential morphological enhancements (taste, colour, nutritional value, etc.) for your crop vs. the potential decrease in yield.

Energy Efficiency and Power Management

LED luminaires are known for their high energy efficiency compared to traditional lighting systems such as high-pressure sodium (HPS). They convert electricity to light more efficiently and are dimmable—reducing energy consumption and operational costs over time.

In addition to the energy savings offered by all high-quality LED lighting systems, dynamically tunable LED lighting systems offer real-time adjustment of the light intensity in response to natural light levels and/or demand on the electrical grid to deliver maximum control over energy.

If you’re considering investing in multi-channel, tunable LED lights, be sure to confirm the fixtures are designed with active load balancing. This means that the power consumption is divided over the active channels so, when one or more channels are not in use, the available power will go the main channel—always ensuring optimized power management and photon efficacy.

Control Protocols

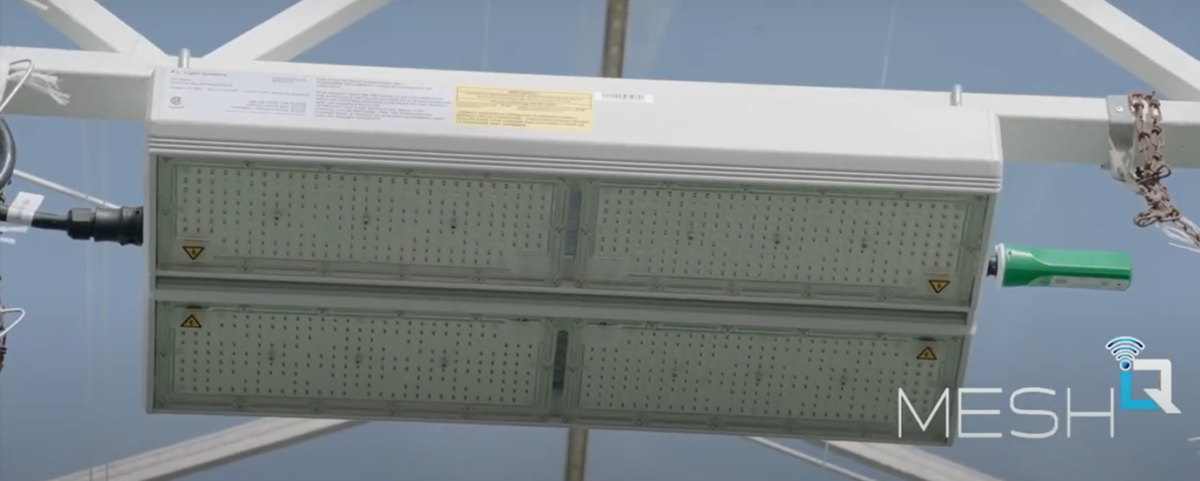

Some lighting manufacturers have developed their own lighting management systems, based on proprietary communications protocols, for real-time adjustments of the light intensity and/or spectrum, as well as power management. P.L. Light System’s MeshIQ-enabled LED luminaires, on the other hand, leverage the Horti Lighting Protocol (HLP) of existing climate control systems like Priva or Hoogendoorn to modulate the lighting intensity and/or spectrum, as well as power management, in real time.

For the grower, the advantage of controlling their lighting through their existing environmental control system vs. a separate “lighting only” managements system, is that the lighting can be integrated into their overall greenhouse power management strategy that includes heating equipment, screen controls, etc. The environmental control system can also be used to manage a facility-wide energy strategy that integrates with utility demand response programs—where the use of equipment in the greenhouse is scheduled / managed to reduce the load on electrical grid during times of peak demand.

Through the use of HLP, P.L. Light Systems’ MeshIQ wireless control system offers seamless plug-and-play integration with the Horti Lighting Protocol module of existing climate control systems—without any proprietary control protocols or monthly subscription fees, as is the case with lighting systems from some other manufacturers. So, as a grower, you are the one who owns and controls your lighting equipment, not the manufacturer.

Cost of Multi-Channel (Dynamic Spectrum) vs. Single Channel (Fixed Spectrum) Lighting Systems

The upfront cost of a dynamically tunable LED systems is typically (significantly) higher than that of a fixed spectrum LED lighting system. Aside from the higher price of the fixtures themselves, there may be additional costs associated with compatible control systems or software (including potential upgrades to activate the HLP module). Tunable LED systems are also more technologically complex than fixed-spectrum lighting, which may necessitate additional training for staff.

We know the ability to fine-tune light spectra, enables growers to influence not only growth rates but also crop qualities like the concentration of desirable compounds, improved flavour, enhanced colour, and shelf life. While customers may be willing to pay more for these crop enhancements, and the incremental revenue potential could offset the cost of the lighting system over time, the initial capex cost outlay may be a barrier for some operations.

Conclusion

Tunable spectrum LED lighting offers commercial growers a powerful tool to enhance crop production through customized light environments. The potential benefits of energy efficiency and improved crop quality are compelling. However, these advantages must be weighed against the challenges of higher initial costs, the complexity of spectrum management, potential impacts on light intensity, and increased technical demands. Growers considering this technology should conduct thorough cost-benefit analyses and stay informed through ongoing research and industry developments to make informed decisions that align with their operational goals.

Check out the video below to learn more about the ParFX Ultra (available in fixed and dynamic spectrums) and the MeshIQ wireless control system.

*It should be noted that due to the high energy of the wavelengths, working under high-intensity (especially blue) light in greenhouses or indoor grows may pose a risk to eye heath. All P.L. Light Systems LED products are independently tested to ensure they meet UL 8800 standards which were introduced in August 2019, specifically to addresses the safety requirements for horticultural lighting equipment intended for installation in both the United States and Canada.

So, for anyone spending a prolonged period in a CEA facility with LED lighting, they should always follow any optical safety instructions indicated on the product labels(s) and it may also be a good idea to wear protective eyewear, specifically engineered for horticultural environments.