Your questions about voltage, power supply, and installing your luminaires (grow lights) are answered by our team of experienced lighting technicians.

What voltage is the best to go with for my application?

We suggest going with the highest voltage available at your facility, which will also be the most efficient. Using a higher voltage for your application can lower driver and conductor losses and increase efficiencies.

Refer to our luminaire spec data sheets for the relationship between voltage, wattage, and amperage.

What Voltage do I have in my building?

Since there are so many field combinations of voltages, an experienced electrician is needed to evaluate your particular site/facility to determine what you have available. The most common voltages will be:

Single phase:

- 120/240V

3 Phase:

- 208/120V

- 480/277V (most common in the United States)

- 600/347V (most common in Canada)

- 400V (special applications)

With the power supplies listed above what voltage can I use to run my luminaires?

Once you know what voltage you have in your building you can move forward with deciding what voltage to use to power your grow lights. If you want a specific voltage installed, transformers can supply voltages not currently installed in your facility. We always recommend speaking with an electrician before deciding what voltage to use to run your luminaires.

With the help of an electrician, and depending on the voltage you have available at your facility, you can use the following voltages to power your luminaires:

- 120V/240V

- 120V/208V

- 277V

- 347V

- 400V

- 480V

Please note that not all light models are available in all voltages. Please refer to luminaire spec sheets for further information or speak with one of our lighting professionals. Also, having a 3-phase service does not mean you have access to voltages that can be used with our lights – please consult a local electrician for more information.

What is the difference between single-phase and 3-phase power supply?

3-phase supply:

- Has three live wires (or lines), and possibly one neutral wire

- Generally supplied to commercial and industrial facilities

- It will typically be 480/277V or 600/347V

- This also depends on your facility design and the transformers used

Single Phase supply:

- Has two live wires (or lines), and one neutral wire

- Generally supplied to residential or small commercial facilities

- Is typically 120/240V in North America

What is the difference between a single-phase load and 3-phase load?

3-Phase Load:

- Some equipment such as motors or fans require connections to all three lines from a three-phase supply.

- This equipment would be classified as a ‘3-Phase Load’

- This equipment requires a 3-phase supply to operate.

Single-Phase Load:

- Other equipment such as luminaires only require connection to either two lines or one line and neutral.

- This equipment would be classified as a ‘Single-Phase Load’

- This equipment can be powered by either a ‘Single-Phase Supply’ or a ‘3-Phase supply’

What is the difference between a ‘Line to Neutral Voltage’, and a ‘Line to Line Voltage’?

Both single and 3-phase supplies can be configured so that single phase-loads receive either a ‘Line to Neutral Voltage’, or a ‘Line to Line Voltage’.

In a Single-Phase Supply system, the lower voltage (typically 120V) will be the ‘Line to Neutral Voltage’ which is the voltage between one of the lines and the neutral. The higher voltage (typically 240V) will be the ‘Line to Line Voltage’. It will be twice the ‘Line to Neutral Voltage’ and is the voltage measured between the two lines.

In a 3-Phase Supply system, the lower voltage (typically 277V or 347V) will be the ‘Line to Neutral Voltage’ which is the measured voltage between one of the three lines and the neutral. The higher voltage (typically 480V or 600V) will be the ‘Line to Line Voltage’. It will be 1.73x the ‘Line to Neutral Voltage’ and is the voltage between any two of the three lines.

Can I use a single-phase luminaire if I have 3-phase power supply?

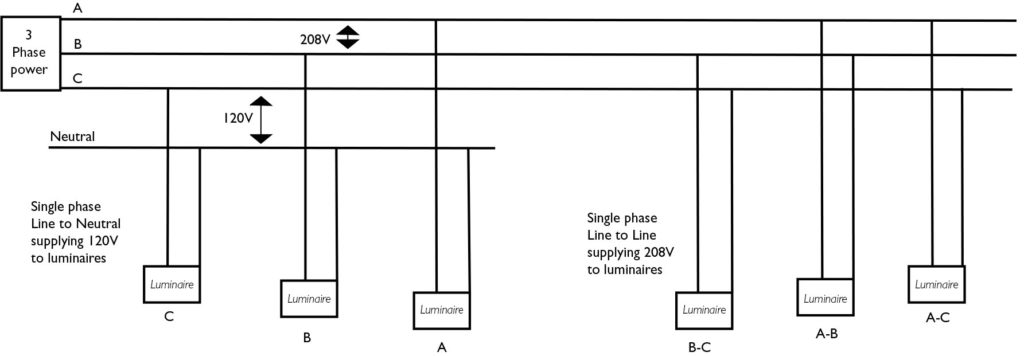

In a 3-phase supply, you can use all three phases for loads such as motors, fans, and other industrial equipment. Since our luminaires operate on a single phase, you can take advantage of a 3-phase supply using either one or two legs to provide either a single-phase line-to-neutral connection or a single-phase line-to-line connection.

The image below helps demonstrate how you can use a single-phase power supply through a 3-phase power supply to power your luminaires configured using a line-to-neutral voltage and line-to-line voltage.

What is the importance of a stable power source, and what are the detrimental results of brownouts, blackouts, etc?

A brownout is a low-voltage condition when the voltage drops. Drivers/Ballasts have a voltage range where they can tolerate a certain percentage of brownouts. Operating the driver outside of this range can be detrimental to the driver/ballasts and reduce its lifetime. It is important to consider having your power monitored in your facility. Monitoring your power quality and voltage variation allows corrective measures to be taken to improve the power quality.

Blackouts are when power is turned off and then on again, either momentarily or for prolonged periods. This could potentially be an issue. Re-striking HID lamps more than two times a day can also be detrimental to the driver. If blackouts are frequent at your facility, consider contacting your utility to resolve the issue (or installing an uninterrupted power supply [UPS] or generator system).

Are there any specific wiring instructions for LEDs?

LED luminaires can be wired in the same way as our traditional HIDs, based on the Voltage required by the light (i.e., 120, 208, 240, 277, 347, 400). Some LEDs can accommodate multiple voltages, whereas others are voltage-specific. The voltage range will be noted on the product label. A luminaire with a product label stating “120V-240V” will accept any of these 3 voltages:120,208, or 240. It will automatically sense the supplied voltage to ensure the same output to the LEDs regardless of the input voltage. A lamp with a product label stating “277V” will only accept a voltage of 277V. LEDs with dimming capability may require separate control wires to control the output of the luminaire.

Do I need to compensate for inrush currents on LED or HID luminaires when I’m wiring my facility?

Inrush current is one of many characteristics that an Electrical Engineer will take into account when designing an electrical installation.

Is there an inrush current I need to be aware of when providing circuit breakers for my luminaires?

Inrush current occurs in all electronic devices due to their electrical characteristics. The magnitude of the inrush current is based on the design of the electronics and the load. This inrush value needs to be provided by the manufacturer of the luminaire for an engineer to determine the correct electrical equipment to use in the installation. Electrical engineers will select breakers and other electrical devices using inrush as one of many variables to design an electrical system that will function correctly. If inrush is not considered when selecting and sequencing the installation of breakers, nuisance tripping can occur and, in some cases, fusing of contacts on contactors. It is always recommended to consult an electrical engineering company when designing a crop cultivation facility.

How to get started with your application:

Never assume what voltage you have and always consult with an experienced electrician who can help you make decisions about what voltage to use.

Please contact us at info@pllight.com for further information, and don’t forget you can always reference our resources page for information about specific luminaires.

Written by:

Trevor Burns – Technical Manager