Controlled environment agriculture makes it easy for growers to control all aspects of growing, such as lighting, HVAC, humidity, and water usage, as well as allowing crops to be produced year-round regardless of weather. In addition, many have eliminated the need for pesticides making it easier for growers to become certified organic. Many customers, especially in urban areas, will pay a premium for organic, hyper local food and is one reason why vertical growing has become increasingly popular. However, startup costs and operating expenses can be prohibitive, with regards land costs, lighting and HVAC systems, and is a reason some vertical farms struggle to make a profit and be competitive with field and greenhouse grown products.

In this article, we will examine some of the pros and cons of growing leafy greens in an indoor vertical tiered system versus a traditional single tiered application to help you fully understand which set up is right for you. Note: This article does not consider vertical systems such as Tower Farms, where greens are grown in vertical towers and utilize sunlight from greenhouses. Instead, we focus on indoor vertical systems, where there is no natural light and growth is dependent on artificial light.

Growing food to feed a growing population

With the rise of LEDs and controlled environment agriculture, we are seeing greater opportunities to efficiently grow food in indoor, vertical racking systems. Growing vertically significantly enhances our land, water and nutrient efficiency, allowing for more crops be grown locally in urban and city centers. Leafy greens, due to their high value, low crop height and quick turnaround time, have been the most popular food being grown in these vertical, stacked layers. With the world’s population projected to grow to 9.6 billion by 2050, the world will need to produce more food for the ever-growing population. Indoor farming, where sunlight is being replaced with artificial lighting, may be a way for us to grow more food in under utilized, and non-traditional agricultural settings like urban city centers.

Low growing crops work better in vertical systems

Since leafy greens are low growing crops with almost no “canopy,” directing light deep into lower leaves is not a problem and makes them ideal for vertical grows. This makes LEDs, which can be placed close to the canopy without burning, the ideal light solution, since we are worried less about shadowing as we would be for tall crops like cannabis or tomatoes. We can also fit many tiers of leafy greens or microgreens close together since the crops do not grow tall, making a situation where you are stacking many tiers more economical. They also have a very fast turnaround, often completing a crop cycle in 2-4 weeks depending on the crop, so you can get our more product in less time compared to other “fruiting” crops.

Vertical indoor farms can be placed in almost any location

LEDs have made it increasingly easy to set up an indoor vertical farm, as they are more energy efficient than traditional HID lighting and give off little heat so they can be placed close to the crop surface. This allows growers to maximize space and grow upwards, enabling them to grow more product in essentially “less” space. In countries where land cost is high, vertical indoor farms can be constructed in under-utilized spaces such as warehouses, vacant buildings, shipping containers and even underground cities, as long as it can be retrofitted for growing. In addition, the closeness to urban populations can reduce the need of transporting food great distances cross-country. Being in a city also allows growers to have a greater pool of skilled labor, however, wages may be higher compared to rural communities.

Energy consumption is higher in vertical systems

While being able to have a vertical farm in any location seems great, growing indoors requires more energy usage to control all aspects of growing. Unlike greenhouses, plants grown indoors rely exclusively on artificial lighting systems for their growth. The energy cost in running lights, such as high-efficiency LEDs, can take up to 30% of the total energy cost, while the remaining is often spent on climate control and system operations. This is one of the major downsides to vertical growing, as energy consumption will be higher since lights and HVAC equipment will need to be running most of the time. This is especially important for leafy greens which need to be kept cool, and you will need fans blowing to keep transpiration rates consistent and control disease.

The constant light, ventilation and cooling uses up extreme amounts of energy and the costs can sometimes be much higher than the output. This could lead to farms closing down due to high associated costs, like this farm in Chicago called “Farmed Here”, where the vegetables had to be sold at a price twice as high as normal organic produce which only a certain demographic can afford. Therefore, it is very important to run an ROI and include all associated operational costs when starting a vertical farm business to ensure profitability. It may also be important to confirm you will have a steady customer base who is willing to pay slightly higher prices than traditional grocery store pricing.

Sensors to control the environment

One thing that can become a problem in vertical farming, is controlling the environment. Very often expensive sensors and software needs to be purchased to ensure high quality and consistent yields in order to be profitable. This is because, even though you are growing in a very controlled environment, you can have areas of high and low light intensity with (especially with poor light planning), or some areas may have high humidity or condensation. Growers can create a lot of microclimates and have poor crop uniformity when they have the wrong vertical farm setup. Every farm setup will be different, and what works for one grower may not work for another. It is also important that the grower have a very good knowledge of plant growth and controlled environment growing, as even though you can incorporate a lot of technology, such as robotics and sensor control, if you are not listening to what the plants need, the technology will only deliver marginal improvements.

Genetics still have a ways to go

While fast growing microgreens might be well suited to vertical farms, fully mature leafy greens genetics are not quite there when it comes to sole source indoor growing. Most have been bred for field and greenhouse growing, and you may experience bottlenecks when it comes to what genetics you chose to grow in your vertical farm. Unfortunately, the market for breeding companies to develop varieties specifically for vertical farms is small as there is not an established market yet for vertical farm growers, and more research and development are needed in this area.

Other areas to consider – Transplants

If you are looking for other ways to be profitable in a vertical farm, one other area to look into, might be growing and selling transplants, such as for cannabis, tomatoes, cucumbers or flowers. Growing transplants can be an economical way to successfully adopt vertical farm production. These starter plants are a high value product and can be grown under very high density in vertical farms, even higher than they can be grown in a greenhouse. These transplants then can be inserted into the current supply chain and be sold to greenhouse and field growers who will produce the end products. The clean controlled environment of a vertical farm can ensure a very high germination rate and a lot of plants can be produced in a small area.

IS GREENHOUSE OR INDOOR GROWING MORE PROFITABLE?

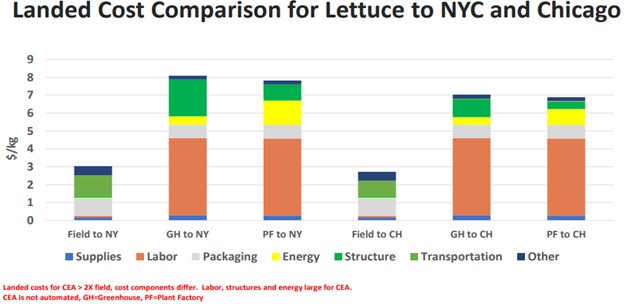

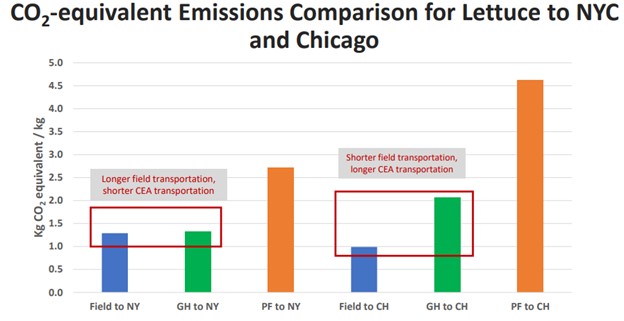

Let’s end this article by looking at the results from a recent study by Neil Mattson, at Cornell, “An Economic and Environmental Comparison of Conventional and Controlled Environment Agriculture (CEA) Supply Chains for Leaf Lettuce to US Cities” where they evaluated the total cost of acquiring and shipping a product, by doing a comparison between warehouse/plant factory (PF) grown vegetables, greenhouse (GH) grown vegetables and field grown vegetables, to see which was more profitable and more eco-friendly.

Field Grown = in California GH & PF = in Chicago & NY

Slides from Indoor Ag Tech presentation by Neil Mattson, Cornell PowerPoint Presentation (indooragtechnyc.com)

They compared greenhouses and plant factories in NY and Chicago to field grown vegetables in California that would be shipped across the country to those cities. The study found that overall operating costs were similar between the greenhouse and plant factories, with greenhouses having more structural costs and plant factories having more energy costs, and that field grown vegetables has the lowest associated costs, even when factoring in cross country shipment. When it came to comparing CO2 emissions, plant factories, due to their high energy load were quite high compared to both greenhouse and field even though they are grown right in the city with significantly lower transportation costs.

This demonstrates that costs to produce and ship a product, even grown right in the city, are quite high, emphasizing the importance of ensuring you have a good ROI before beginning a vertical indoor farm. However, since customers are usually willing to pay more for local grown veggies, especially in off-season months, the high costs may work out depending on the location. Unfortunately, the high energy usage compared to field and greenhouses, makes vertical plant factories more unsustainable in terms of environmental footprints, warranting more work in terms of energy efficiency for these types of operations to truly gain benefits from being grown right in the city.

CONCLUSION

As we can see there are many advantages and disadvantages to growing greens vertically. Being able to boost crop production in city centers may be a way to help increase food for a growing population, but it should be done in a sustainable way that does not add to climate change issues. In addition, most other advantages of vertical growing such as, allowing crops to grow year-round, using significantly less water, being able to grow more organic crops and less exposure to chemicals and disease are also advantages of greenhouse growing, so figuring out what type of growing makes sense for you will be a big deciding factor in whether you want to grow in a vertical “plant factory” or more traditional greenhouse setting.