Should I use HPS or LED for growing Cannabis?

“What lighting source should I use for my licensed cannabis grow?” “I am comparing LED to HPS for my cannabis operation. Which source do you recommend?” These are questions people ask us almost daily. Like many aspects of growing, deciding if you should grow under HPS (high-pressure sodium) or LED does not have a silver bullet answer! There are a lot of variables that need to be considered and then prioritized to your own operational needs. This is an important step in understanding which type of lighting will fit this critical investment.

To figure out what type of horticultural lighting you should use, begin by rating the following six factors: Budget, Maintenance, Electrical costs, HVAC requirements, Growing requirements, and Spectrum, in order of your priorities. We will overview all these factors and then a Pros & Cons chart comparing double-ended (DE) HPS, LED, and a hybrid HPS-LED system to see which lighting type meets your needs.

Let’s first go over the six factors, beginning with budget.

1. Budget

The amount you have to invest and your return on investment should be key things to consider when buying a new lighting system.

Capex

- An all-LED system can be approximately 3 to 4 times the cost of an all-HPS DE system

- LED fixtures may be eligible for locally available hydro incentives that could reduce approximately 10-25% of the LED system cost if DLC listed

If you want to learn more about local rebate programs in the USA and Canada then download our “Energy Rebate and Incentive Guide”

Opex

Warranty

- DE HPS fixtures – Have a 3-year warranty. HPS lamps have a 4-year warranty or up to 10,000 burning hours

- LED fixtures – Have a 5-year warranty, or up to 50,000 hour lifetime (a requirement to be eligible for DLC listing)

2. Maintenance

Both HPS and LED luminaires need to be cleaned and maintained to keep them working efficiently and at their highest output. HPS lights require more maintenance than LEDs since they also require re-lamping and reflector cleaning.

DE HPS

- Re-lamping costs and associated labor, approximately every 1-4 years depending on your burning hours and ROI (return on investment)

- Reflector cleaning and associated labor, approximately every 1-2 years depending on your environment and resources

LED

- Lens cleaning and associated labor, approximately every 1-2 years depending on your environment and resources

To see what’s involved with cleaning and maintaining HPS luminaires, watch our video on Reflector and Fixture Cleaning as well as our video on How to Install a DE lamp.

3. Electrical Supply & Operating Costs

What is your current supply capacity? Do you have a limited supply that you will need to work within? Will you need to factor in the cost of adding a transformer to expand your supply? These are all things you should consider when deciding what type of lighting you should use for your crop.

First, you should figure out what the cost per kW is. You can easily do the math:

# lighting hours annually x actual wattage of the fixtures x # of fixtures) /1000 x $/kW.

Below we have two examples showing the difference between HPS and LED:

Example 1. DE HPS – (4000 hours x 1045W x 100 Fixtures)/1000 x $0.12 = $50,160.00 annual electrical operating cost for 100 x 1000W DE HPS

Example 2. LED (4000 hours x 640W x 100 Fixtures) /1000 x $0.12 = $30,720.00 annual electrical operating cost for 100 x 640W LED

This means a potential 38.8% kW savings

Measuring fixture efficacy is important to determine the efficiency of the light source at converting watts into photons (PPE). The higher the PPE, the better the luminaire is. It is measured in micromoles per Joule (µmol/J) and is calculated by dividing the µmol/s1 by the wattage.

Let’s look at two examples:

Example 1. DE HPS 2150µmol/s1 divided by 1045W = 2.06µmol/J

Example 2. LED 2200µmol/s divided by 672W = 3.3µmol/J

As we can see, the LED has a higher efficiency and is better at converting photons into PAR energy.

Check out our Light Energy Calculator to find out more to compare efficiencies across different lighting technologies.

4. HVAC Requirements

HVAC requirements vary based on many factors and should be assessed to determine what lighting will fit into your application.

Below we outline some things to consider when figuring out your HVAC needs.

- Geographic location: year-round temperatures can influence your HVAC needs.

- Indoor vs. Greenhouse applications will have varying HVAC requirements.

Indoor facility: The cost to cool your grow can be one of your highest production expenses. Your AC load is based on the amount of BTUs produced from your luminaires. This is simple math as 1 watt equals 3.412 BTUs. No matter what 1000W HPS fixture you use, the BTUs from that fixture will be 3412.

Calculate the BTU/h to size your AC = # fixtures x actual wattage x 3.41:

Example 1. DE HPS 100 Fixtures x 1045W x 3.41 = 356,345 BTU/h

Example 2. LED 100 Fixtures x 640W x 3.41 = 218,240 BTU/h = Potential 38.8% BTU/h savings

Example 3. Hybrid 1:1 50 x 1045W DE HPS+50 x 640W LED x 3.41 = 287,292.5 BTU/h

Greenhouse facility: DE HPS can reduce additional greenhouse heating by 40% in colder winter climates vs. LED.

5. Growing Practices

Growing vertically or in a traditional single-tiered facility can help you determine if you should use HID or LED luminaires. Let’s look at the differences between them both.

Vertical racking – Maximize your vertical footprint by minimizing the distance between shelves with fixtures closer to the crop.

- Vertical racking can increase your canopy by 100% per additional tier in the same linear footprint, with yield increasing slightly less by approx. 80% per tier due to smaller plants/less yield—but possibly more frequent turns.

- LEDs are best suited to close-to-canopy mounting due to their lowered heat load.

- Detailed ROI is needed to include HVAC adjustments to manage vertical microclimates on each tier.

Single layer – Mounting height restrictions and available distance from the canopy should be considered. HPS lights require at least 3 feet from the canopy.

6. Spectrum

LED

- Tolerance & resources for learning curve of how plants react under different spectrums to reach optimum levels

- Rebalancing inputs: temperature, CO2, irrigation, fertigation, and possibly humidity.

- Opportunity to affect morphology & metabolic processes.

DE HPS

- Tried & trusted spectrum for experienced growers, confidence in growth & yield results.

- No spectral variety or opportunity to further affect morphology or metabolic processes, unless mixing different HID spectrums i.e. adding some blue to the flower cycle with CMH or MH.

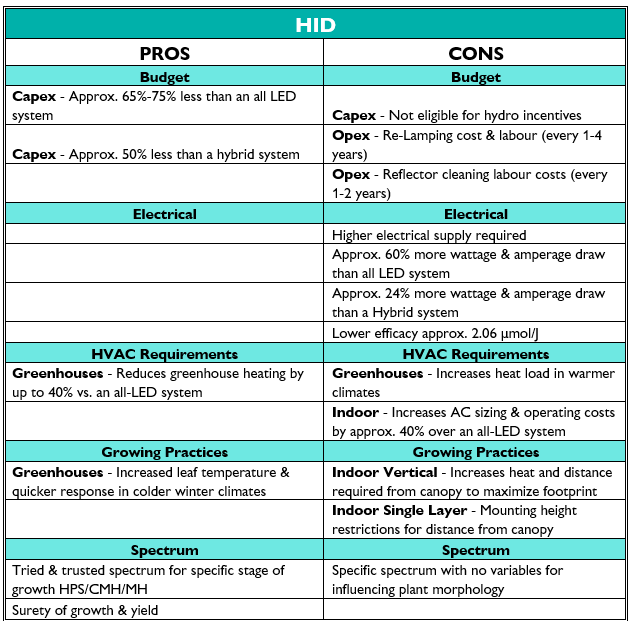

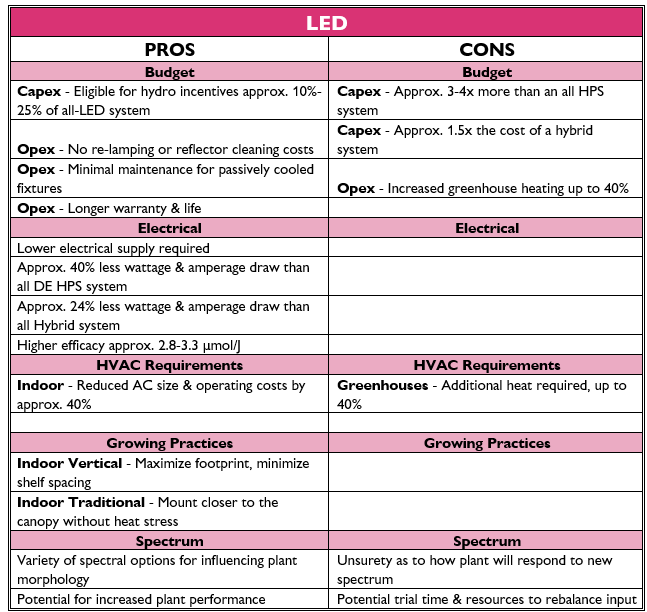

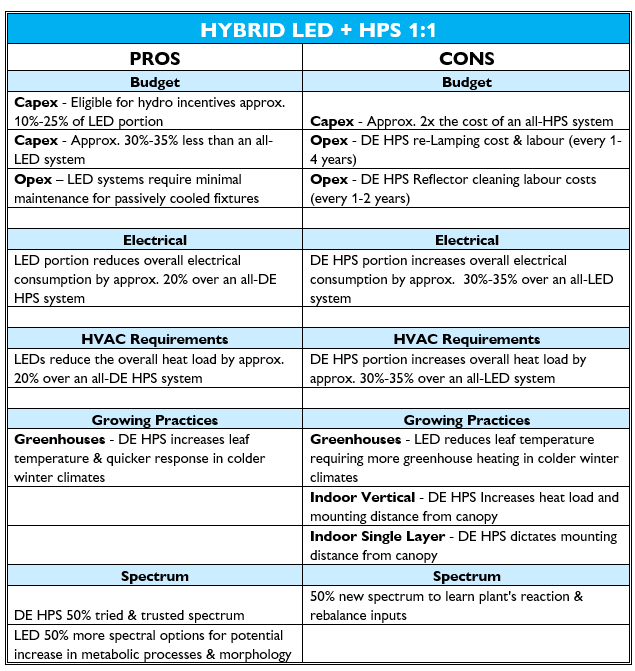

PROS AND CONS:

In the following charts, we overview the pros and cons of each type of lighting—including a hybrid LED-HPS system, to help determine what type of lighting system will work best for your application.

*Example calculations & savings are based on 640W LED & 1045W DE HPS, hybrid solution is based on 1:1 DE HPS + LED, associated costs based on a $300 DE HPS fixture & $900 LED

Bottom Line:

With all these factors above, how do we answer our initial question? Quite frankly, there is no simple solution. Every grow is different – from different strains, varying climates by geography, multiple styles of growers, indoor versus greenhouse, and more. All these factors will weigh heavily on what is better for you.

Remember to analyze and prioritize your key deciding factors and do your homework on the best product to meet your needs and budget. Lighting is a long-term investment, so partner with a quality manufacturer that will understand your needs and provide a detailed, professional light plan with after-sales support.

For more information on growing cannabis, download our Cannabis Cultivation Guide for advice on growing under both Led and HID luminaires.