Disclaimer Nothing in PL Light Systems, including, but not limited to, written, visual, or editorial content, or external links on the website and digital journal, shall in any way be considered as promoting any illegal or illicit activities within your jurisdiction.

Things you may not have considered (but really should) when selecting an LED lighting system

If you’ve been doing some research with the intent to purchase LED lights for your CEA facility, you’ve no doubt discovered there are a plethora of product options. As is the case in any product category, some offerings are clearly better than others. However, sometimes it’s hard to know what’s just a great marketing spin vs. a product that truly addresses your needs as a commercial grower. At P.L. Light Systems, we always recommend growers consider the evidence-based data that enables them to make an educated decision when selecting a lighting system to meet their needs and cultivation goals.

Of course, growers should validate the manufacturer’s performance claims for any luminaire against the actual tested performance metrics posted on the DLC Horti QPL. It’s equally important that they understand how to interpret that information from a practical context. Some of the key aspects you should consider include:

LIGHT OUTPUT: COST PER USEABLE MICROMOLES

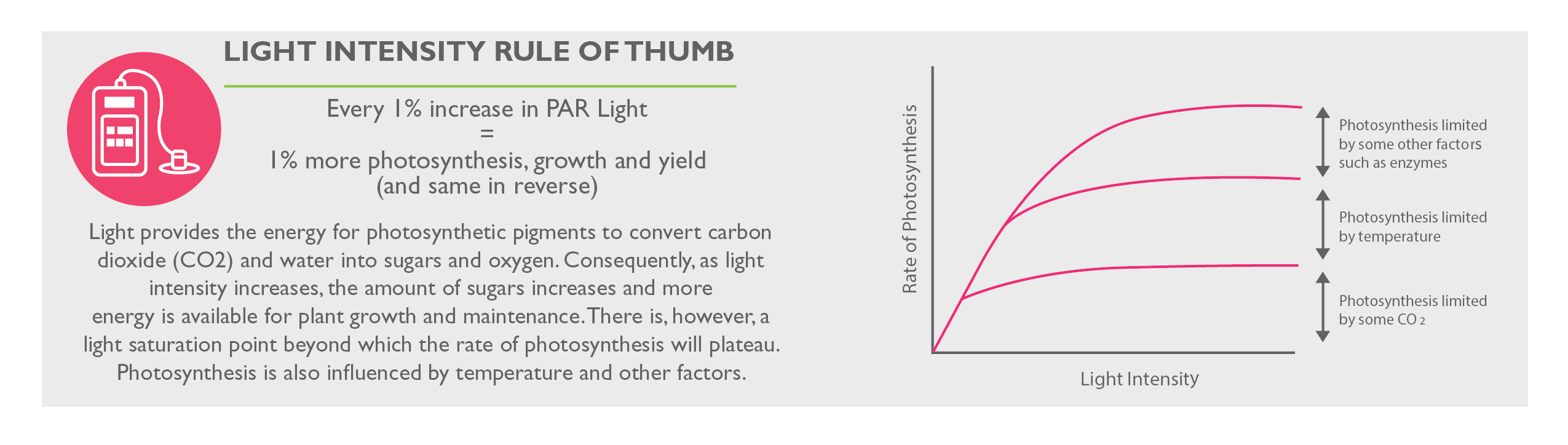

We know there is a linear correlation between light intensity and photosynthesis, i.e., as PAR light intensity increases, photosynthesis will also increase. There is, however, a light saturation point—beyond which the rate of photosynthesis will plateau.

This is true even with crops that require very high light levels. For example, research has shown the benefits of increased light intensity (morphology, physiology & yield) for cannabis plateaus at 1800 μmol/s. So, even though some LED luminaires can deliver incredibly high PPF (some as high as 4200 μmol/s), the grower needs to ask themselves how much light output they will actually use. Although the output may be impressive, a super high output lamp may not be the best solution if your crops require lower light levels and you need to dim the lights by ≥50%. Purchasing a luminaire you cannot use at its full performance potential may not make sense since you’d still be paying for all the wasted / unusable light.

This is true even with crops that require very high light levels. For example, research has shown the benefits of increased light intensity (morphology, physiology & yield) for cannabis plateaus at 1800 μmol/s. So, even though some LED luminaires can deliver incredibly high PPF (some as high as 4200 μmol/s), the grower needs to ask themselves how much light output they will actually use. Although the output may be impressive, a super high output lamp may not be the best solution if your crops require lower light levels and you need to dim the lights by ≥50%. Purchasing a luminaire you cannot use at its full performance potential may not make sense since you’d still be paying for all the wasted / unusable light.

So, when considering a new LED lighting system, be sure to evaluate the light output against the actual light requirements (current and future) for the crops you are growing. Drill into the cost per useable micromoles of light from the product, i.e. divide the cost of the luminaire by the number of micromoles, you’ll actually be using—not the number of micromoles the luminaire can produce at full output.

Another thing to watch for when presented with an ROI calculation by an LED luminaire manufacturer is whether the parameter data they have based the comparison on is accurate. Some manufacturers will, for example, claim an undervalued PPFD for a 1000W HPS lamp to understate the ROI period for their LEDs. The de-rated PPFD (incl. accounted light loss from the reflector, etc.) of a 1000W electronic DE HPS should be around 1840 μmol/s. Many LED manufacturers will claim the significantly lower PPFD of an old mogul-based lamp designed for obsolete magnetic ballast HPS.

POWER CONSUMPTION: ANNUAL OPERATING COST

One of the key reasons growers are making the switch from HPS to LED lighting is to reduce their energy consumption. Growers often assume a luminaire has a lower wattage simply because it uses LED technology. They can be surprised to learn that, at full output, a super-high output LED luminaire like the 4200 μmol/s mentioned previously has a higher power draw (1500W) than a 1000W HPS (1045W). By comparison, the TriPlane HO RWMB (which delivers an equivalent light output vs. a 1000W DE HPS at 2100 μmol/s) draws 658.5W of power and the TriPlane HO Daylight draws 643.8W. So, when considering the ROI of their new lighting installation, the customer should calculate the annual operating cost per kW. To calculate this:

# lighting hours annually x actual wattage of the fixtures x # of fixtures) /1000 x $/kWh

Below are some sample calculations comparing the cost / kW for 1000W DE HPS, 1500W LED & the TriPlane HO luminaires.

For demonstration purposes, the samples below assume a total of 4,380 lighting hours/year (12 hrs/day for 365 days) and an electricity cost of $0.12/kWh. These examples also assume the same quantity of LED vs. HPS luminaires since the directional nature of LED light distribution does not allow for wider spacing—irrespective of higher light output—if light uniformity levels across the crop are to be maintained.

Example: NXT DE 1000W HPS (P.L. Light Systems)

(4380 hours x 1045W x 100 Fixtures)/1000 x $0.12 = $54,925.20 annual electrical operating cost for 100 x 1000W DE HPS

Example: 1500W LED (other horti lighting manufacturer)

(4380 hours x 1500W x 100 Fixtures) /1000 x $0.12 = $78,840.00 annual electrical operating cost for 100 x 1500W LEDs

Example TriPlane HO RWMB LED (P.L. Light Systems)

(4380 hours x 658.5W x 100 Fixtures) /1000 x $0.12 = $34,610.76 annual electrical operating cost for 100 x 685.5W LEDs

Example TriPlane LO RWMB LED (P.L. Light Systems)

(4380 hours x 380.7W x 100 Fixtures) /1000 x $0.12 = $20,009.60 annual electrical operating cost for 100 x 380.7W LED

In many jurisdictions—including California where there is an urgent need to reduce loads on the electrical grid—energy conservation rebates are based on the customer’s reduction in kWH when upgrading their lighting to newer, more energy-efficient technologies. So, depending on the number of LEDs required to achieve the equivalent light levels and uniformity of an existing 1000W HPS installation, a grower could end up with even higher lighting energy consumption if they opt to install LED lights with a power draw ≥1000W—excluding them from any rebate qualifications.

Other critical questions for the grower include, What is your current electrical supply capacity? Do you have a limited electrical supply that you will need to work within? Will you need to factor in the cost of adding a transformer to expand your electrical supply? These are all things a grower should consider when contemplating retrofitting their existing lighting with higher-wattage LED luminaires—either in a hybrid or full LED application.

THE IMPORTANCE OF POWER FACTOR & TOTAL HARMONIC DISTORTION

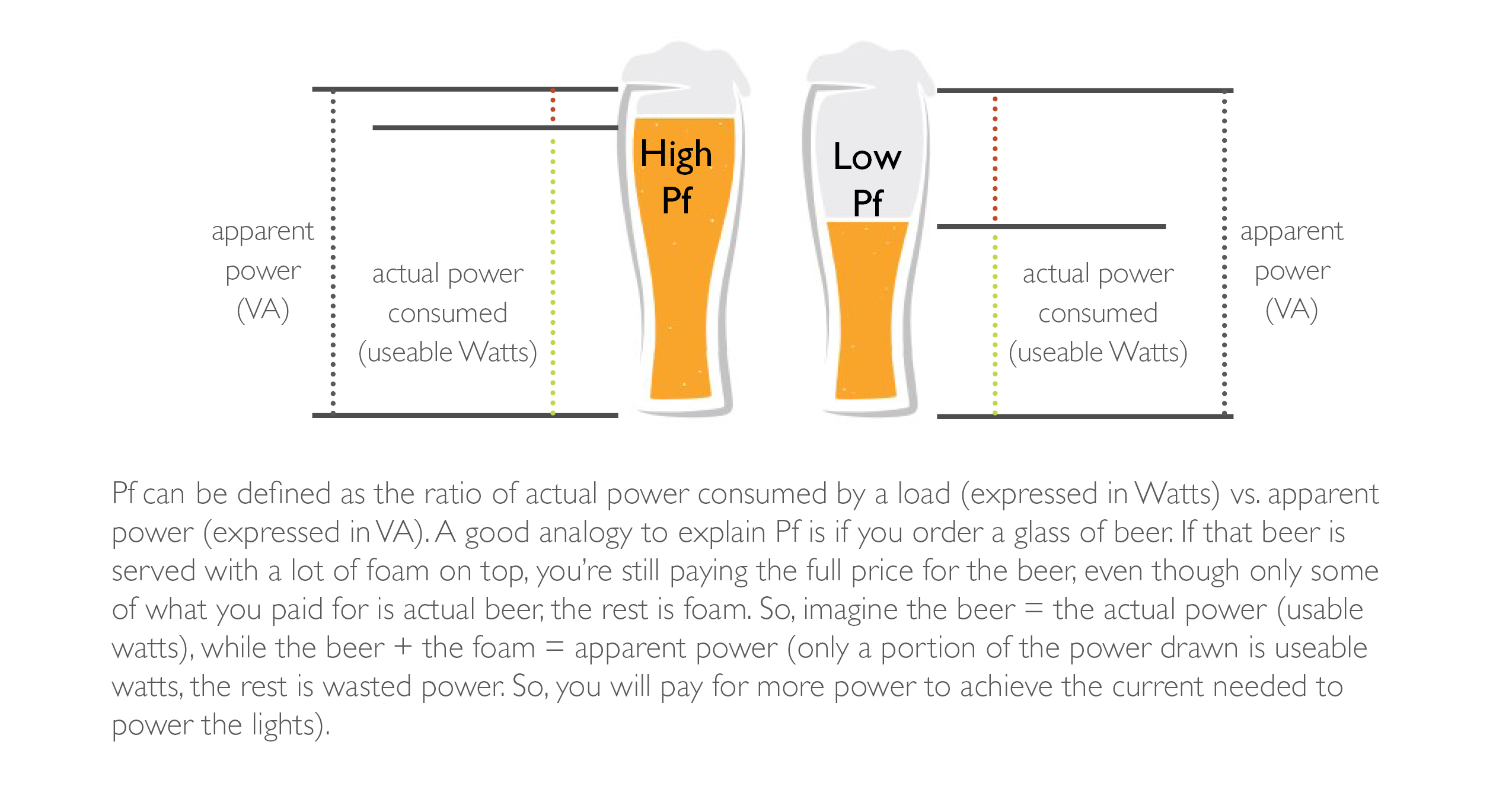

Power Factor is an important, but commonly overlooked, specification when purchasing luminaires, as it is an expression of energy efficiency. The lower the power factor (Pf), the less efficient the power usage. Low power factor can result in:

- A required increase in conductor and equipment sizes

- Heat damage to insulation and other electrical field wiring components

- Increased overall electrical costs because the lower power factor requires a higher current to supply the loads.

For example, the Wega, with a power draw of 769.9W and a Pf of 0.935 would be using 6.5% more electricity to deliver the 769.9W needed to run the luminaire. Put another way, of the 769.9 watts rated requirement, the Wega loses 6.5% of the electricity consumed and paid for, equating to 769.9 x 6.5% = 50.04W of energy waste per light. By comparison, the TriPlane HO has a Pf of 0.983 (RWMB) / 0.987 (Daylight), resulting in a discrepancy of only 1.7% or 1.3% (depending on the spectrum). With the sky-high cost of electricity today, an incremental electricity consumption of 6.5% (multiplied by “x” number of lamps) to compensate for the wasted power will really add up.

Pf can be defined as the ratio of actual power consumed by a load (expressed in Watts) vs. apparent power (expressed in VA). A good analogy to explain Pf is if you order a glass of beer. If that beer is served with a lot of foam on top, you’re still paying the full price, even if you’re paying for mostly foam. So, imagine the beer = the actual power (usable watts) and the beer + the foam = apparent power (only a portion of the power drawn is useable watts, the rest is wasted power). So, you will pay for more power to achieve the current needed to power the lights.

Pf is also closely related to a luminaire’s Total Harmonic Distortion (THD)—typically the higher the Pf, the lower the THD. THD indicates the level of distortion of the line voltage or current due to harmonics in the signal. THD is expressed as a % and should be as low as possible and should never exceed 10%. High THD can cause stress on equipment and the electrical distribution network, resulting in increased maintenance costs and downtime. Some energy rebate programs also have a max THD threshold for luminaires to qualify.

Both the power factor and THD for a luminaire can be validated on the DLC Hort QPL, so always be sure to do your homework!