Disclaimer Nothing in PL Light Systems including, but not limited to, written, visual, or editorial content, or external links on the website and digital journal, shall in any way be considered as promoting any illegal or illicit activities within your jurisdiction.

_________

“What lighting source should I use for my licensed cannabis grow?”; “I am comparing LED to HPS for my cannabis operation. Which source do you recommend?” These are questions people ask me almost on a daily basis. We have covered this question in past posts on our blog, like this one by our very own head of marketing: LEDs vs Traditional Lighting but most cannabis growers know that this crop is different than most and many growers have experimented with lighting technologies on a small scale to find they can sometimes increase terpenes and THC levels just by changing their light sources. To begin, let’s unpack the information that exists on this complex topic.

Unpacking Existing Information

There is a lot of information out there on the internet from various growers and lighting suppliers. You can find a contradiction to almost every point you find! Most growers agree that for young plants through the veg stage of growth you will want to have a light source with a good amount of blue light or even white (full spectrum) lighting. The main reason for this is to reduce internode stretching to produce a stockier, healthier plant.

After veg and moving to flower, most growers also agree that switching to a light source with more of the red spectrum is better for flowering. The old standard has been to use either CMH or fluorescents in veg and switch to HPS into flower. This is the tried and true lighting recipe for indoor cannabis growers. By far the majority of cannabis produced in North America today is grown in this way. With the onslaught of LED lighting manufacturers jumping into this new “green rush” of opportunities we are seeing this standard lighting recipe being challenged more and more.

Lighting and Cannabis Qualities

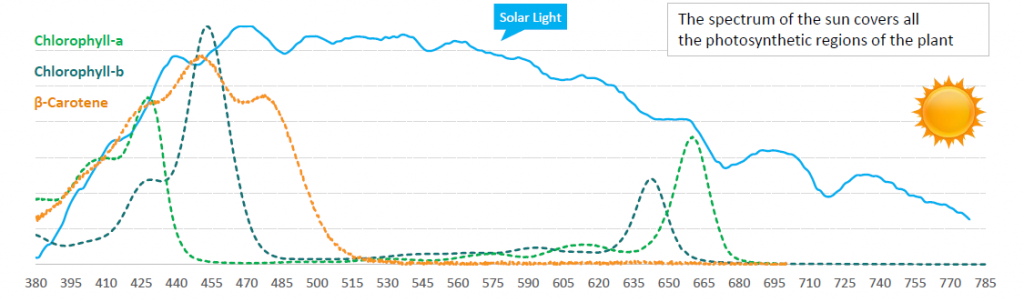

Most of these “new to horticulture” LED manufacturers are making claims that you should be using a full spectrum LED in flower to truly maximize plant terpenes and THC levels. But is this really true? See the graph below comparing what parts of the light spectrum is used for photosynthesis compared to the full spectrum light from the sun.

These claims are not totally bogus however. We are now seeing real results that a bit more blue light in flower or at the very end of the flowering stage does increase terpenes/THC levels. Depending on where you search you will find these amounts vary from minimal 3-5% to unreal amounts of 26-38% as in this article from HortiDaily supplied by an LED manufacturer.

Does this article answer our very first question? Let’s break it down and see. Upon further investigation, the crops in question were grown entirely under each light source. Not in a veg room under one type of light and then moved to flower. For this reason, the HPS plants stretched in veg and were not off to a healthy start!

For this reason alone, this research should be thrown out.

As a plant that does not have sufficient lighting in veg will not produce as well in flower. That said, the spectrum with the most blue did produce the flower with the most terpenes and THC.

This is congruent with other findings that some added blue in flower will cause this. But the reason we see these amounts vary is because every strain reacts differently to different spectrums. Keep in mind that the cannabis plant grew in nature all over the world at different longitudes with different spectrums. With all of the variations of cannabis strains in today’s market made from these ancestral plants from all over the world, each will perform differently under different spectrums.

Cannabis Research in Canada

In countries like Canada, where the federal government has legalized recreational cannabis, there is the ability to do more research. The University of Guelph is one organization that is leading the way in this research. As he states in this article from HortiDaily — Michael Dixon, Director of Environmental Control Research at Guelph says: “We have found that the optimal LED spectral recipe changes with every strain of cannabis.” This is a very important statement for growers to consider! Will you be growing just one strain in your grow the entire time? If not, what spectrum do you choose? Yet if the added blue light in flower only increases your THC levels by 4% is there a justifiable ROI in the cost of the added light spectrum?? If so, can you do that by just adding a few MH lamps? Or does the ROI make sense to go all LED? (1000w DE MH lamps are now available with the PL Light NXT 1000w DE fixtures).

The bottom line that I can share with you, from my perspective where I get visibility to lots of opinions on the topic, see lots of sales and growth cycles, talk to lots of growers, is this: We are still in the investigative and development stage with LED technology in this sector.

No manufacturer , supplier, or customer can state they know the optimum LED recipe for cannabis (or tomato’s, or cucumbers, or orchids, etc.) as nobody has tested and tried multiple, different spectrums with each one being tuned to a specific strain or cultivar of each plant type to be able to render a quantifiable opinion.

LED technology has only been available on a commercial level in the horticultural industry for around three years. So realistically, they would only have had time to trial a limited number of spectrums that may yield good results for one or two strains/cultivars. We simply have not had the technology long enough to perform the testing needed!

Greenhouse Application

What about growing in a greenhouse? From our graph above showing the spectrum of sunlight compared to that used for photosynthesis is there any benefit for using a light source where you can dial in the spectrum to add more blue? The natural light received by your crop in a greenhouse will cover all of your light spectrum needs. So the big question for greenhouse grows should center more around the ROI comparisons between LED and HPS — not about light spectrum needs. This is not something you will hear from light manufacturers of LED lighting. Your LED-only supplier will have you believe you NEED their spectrum specifically!

Determining ROI between LED and HPS

When it comes to building an ROI comparing LED versus HPS be careful with results that are supplied by manufacturers of only one type of light source. I have seen manufacturers on both sides of the argument manipulate numbers to favor their specific light source. Below is an outline of things to look out for when receiving an ROI comparing lighting technologies:

Efficiencies

With LEDs most will use μmol/J (“Micromoles per joule” with joule being a measurement of watts). This is easy math you can do yourself.

To use the PL Light TopLED R/MB as an example: 320W fixture with PPF of 860 μmol is 2.7 μmol/J (860 / 320 = 2.6875) where the 1000W DE HPS has an output of 2100 μmol is 2.1 μmol/J (2100 / 1000 = 2.1). This is important because I have sat in many presentations, by LED manufacturers, who show how quickly they can hit a good ROI with their LED and use 1.85 μmol/j as their HPS comparison. They’re not lying about this but they are using the old single-ended screw in 1000w HPS lamp in the comparison. These lamps have an output of 1850 μmols at 1000w. But, it is an old technology only in use by small hobby grows these days. I have seen manufacturers use as low as 1.7 μmol/J for HPS which would be the equivalent to the end of life of the old HPS technology.

Light Planning

When comparing both technologies, always compare light levels of the entire grow and not just fixture to fixture. I cannot stress enough that there is no such thing as a 1-for-1 replacement of HPS by LED! That simply does not exist in the marketplace. Yes, there are LED fixtures that exist when measured directly beneath the fixture. The output looks equal to or even greater than an HPS. But, when you move the PAR sensor any direction from centered beneath the LED the light level decreases much more under the LED than any HPS fixture!

ALWAYS ask for a light plan that shows an average light level in micromoles AND a uniformity average (hopefully above 90% uniformity). Most LEDs are a very directional source of lighting. If a crop is grown under lighting that is not uniform across your canopy but instead has “hot spots” and “dark spots” it will cause you trouble as the hot spots will use more water, evaporate water, absorb nutrients, etc. at a different rate of speed then the dark spots! To truly have an “apples to apples” comparison be sure to compare light plans with the same targeted light level in micromoles and close to the same average uniformity number. If a supplier cannot provide you with these numbers then it may not be someone you should be considering.

Heating/Cooling

Another area you should always do your own math on is the BTU calculation for your grow room. Yes, LEDs produce less heat than HPS and this can be the deciding factor. As the cost to cool your grow room can be one of your highest production costs. Your AC load is based on the amount of BTUs produced from your fixtures. This is simple math as 1 watt equals 3.412 BTUs. No matter what 1000w HPS fixture you use the BTUs from that fixture will be 3412!

Do this math with your LEDs as well. The PL Light TopLED is 320 watts so the BTUs will be 1092 BTUs. While that looks like a big savings it will take at least two times the amount of our LEDs to get to the same light level as a 1000w HPS. On the other side of this argument is that the LED fixtures do not provide the radiant heat as HPS and your crop roots will perform better with warmth. It is proven that there is a direct correlation between heat and crop production. Plants grow slower, producing less fruit the colder they are. In northern climates many growers rely on the heat from HPS to warm their crops.

Canopy Penetration

This is a big consideration to consider when comparing these technologies. There is no easy math to calculate an ROI for this but when comparing light plans from one source of light to another be sure to take into consideration the distance of the light source from the canopy.

There is a big misconception in the industry stemming from the LED suppliers that the ability to have your LED lights so much closer to your crop will help increase production lower into the crop. This could not be further from the truth! When your light source is closer to the top of the canopy than the shadows created from the top layer of leaves are much bigger than if the light was further away. (Use a flashlight and make a shadow on a wall with your hand. Watch how the shadow grows as you get the light closer to your hand). Also, light penetration into the crop comes from the crossover between fixtures.

HPS or LED: A Key Factor to Consider

One of the reasons you still hear people claiming that LED is not ready for commercial cannabis grows is because the reflectors from an HPS fixture mounted 4 ft from the canopy will provide a wide angle of light so the crop will receive light from the fixture directly above as well as the lights from the next row over and even 2-3 rows away. This light is coming in from different angles hitting the crop beneath the canopy leaves that are causing shadows from the light above. This does not happen if you are using an LED fixture that is a big panel of LEDs or made up of multiple LED bars where they have to be mounted 9-12 inches from the canopy. You get no crossover from the fixtures but only shadowing from the top of the canopy.

It was only after companies like P.L. Light and Philips* introduced LED fixtures specifically engineered for truss mounting in a greenhouse, that growers really adopted this technology. These products enabled even the indoor grower to maintain some distance between the LED fixtures and the plant canopy, and resulted in production similar to growing under HPS. (*In the United States, Philips has taken the stance that they will not support sales into the cannabis industry as it is not recognized to be legal by the federal government)

LED or HPS for Cannabis? The Answer is…

With all of these factors above, how do we answer our initial questions?? Quite frankly, there is no simple answer! Every grow is different – from different: strains being grown, growing climates by geography, style of growers, indoor versus greenhouse, etc. All of these factors will weigh heavy on what is better for you!

The best advice I have is to get a comparison of your ROI done by a versatile company. One that can offer both technologies where you can have light plans designed to the same levels with both technologies. Don’t trust just what the LED guy says or the only HPS guy says. Look at both, do your own math. Know what works for the strains you are growing and measure your own ROI. The easiest way to do this is going to this link and ask your local PL Light Territory Manager for advice as we are the “Lighting Knowledge Company” and whether you decide to use LED or HPS, you will get a true and honest comparison of both technologies.