Lighting is perhaps one of the most important aspects of growing a crop. Just as you would spend money and time to upkeep a car, a lighting system needs to be maintained to get the most out of it. Grow lights should be cleaned, re-lamped, and tested to ensure they work well. Otherwise, you can run into problems, such as slowed crop growth, increased crop cycles, and overall loss in crop productivity, thus reducing profits. In this article, we go over 10 ways to maintain luminaires so you continue to have optimum PAR output while ensuring high crop yields and peak efficiency.

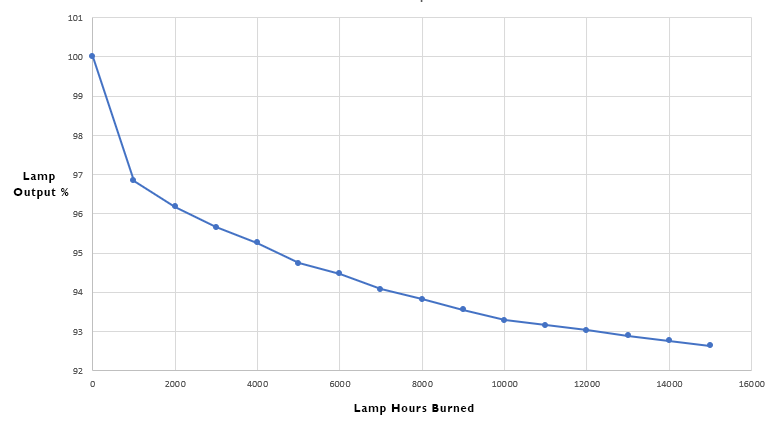

1. Keep a re-lamping schedule. Lamps used in horticultural settings do not “burn out” like household lamps but must be replaced after so many hours of use. As you can see from the chart below, light output diminishes after every 1000 hours of use with HPS lamps. We recommend re-lamping after 10,000 hours of use, which may be anywhere from 2-5 years depending on how often you use your lights. It is important to note that every 1% loss in light equals a 1% percent loss in production. After 10,000 hours of use, your light output has diminished by 7-8%. For CMH or MH lamps, that interval is even earlier. They need to be replaced at around 8000 hours. Decreased lamp output is even more pronounced in sole-source indoor applications, where there is no natural sunlight to offset the associated depreciation in light. These growers may see a greater loss in crop productivity as they go over 10,000 burning hours.

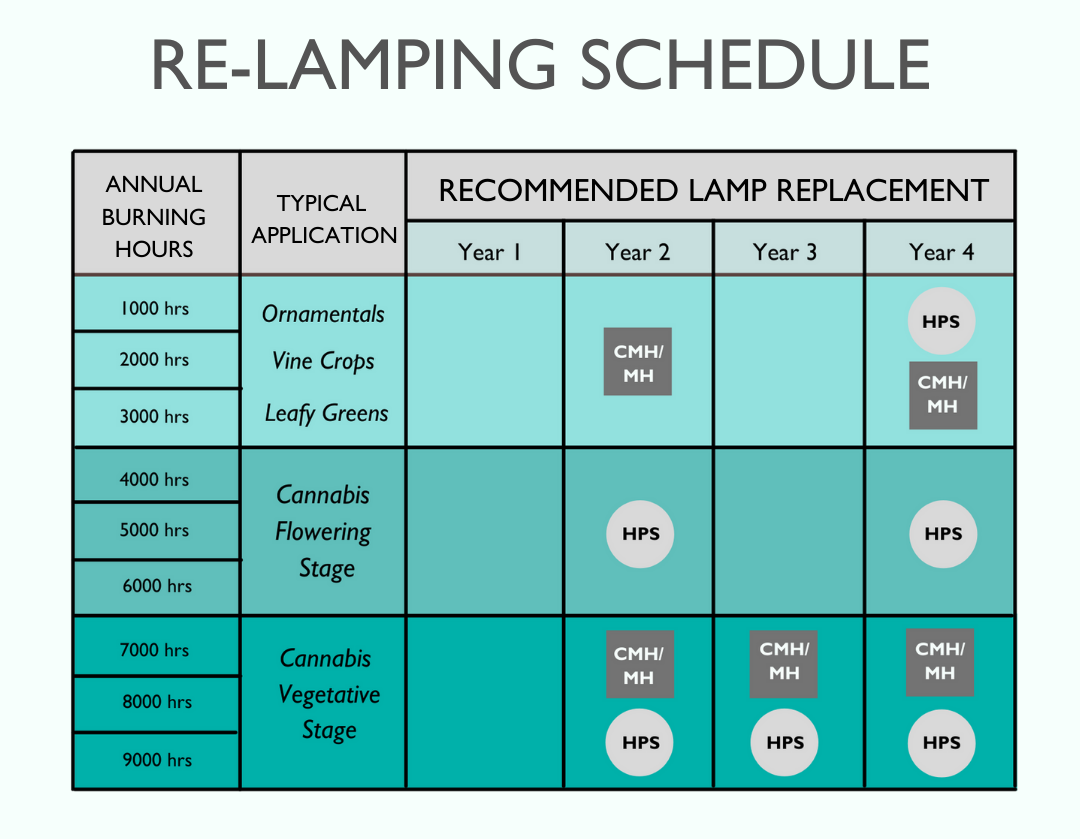

Based on hours of use each year, we recommend making a re-lamping schedule so you don’t forget to purchase lamps for when you need them. Below we have created a chart showing approximately when to re-lamp your HPS and/or MH/CMH luminaires based on crop type. Additionally, when you are re-lamping, make sure your lamps are installed correctly or you can experience lamp failure. Refer to our video on how to install a double-ended lamp for further guidance.

2. Check your light output using a light meter to see how much light you are really getting. This can be done after 2-3 years of luminaire use. We recommend the use of a quantum sensor (PAR sensor) for the measurement. To get a measurement, stand in the middle between 4 lights and take measurements at the crop level. Take note of any shadows, objects, or obstructions that might interfere with the reading. You can also ask one of our sales managers to come by and assist with measurements if things are unclear or have problems. Something to also be aware of is your light meter calibration. Just like other equipment (a pH meter, for example), a light meter also needs to be calibrated to ensure accurate readings. Refer to your light sensor manual on how to calibrate.

3. Look for consistency in your lighting. Do all the lamps look the same in light output when you look up at them, or do some look dimmer than others? If so, this may mean that you need to re-lamp. Having uneven light output will affect growth and yields.

4. Clean your reflectors every year. Reflectors can become dirty with dust and grime, thus reducing light output by up to 10%. A simple way to increase your output is to clean them with a simple vinegar and water solution. The best time to do this is in the summer when you are not using your luminaires. Refer to our maintenance video for more info.

5. Remember to dust off and clean your outdoor K-LUX, or other outdoor light sensors. These sensors are designed to tell you when natural sunset and sunrise occur, so your climate software knows when to turn on or off your lights. If they are dusty or dirty, they may be getting faulty readings and your luminaires may be turning on unnecessarily early and wasting light when you don’t need it.

6. Remember to clean shade compounds. If you are using whitewashing or other shade compounds on your greenhouse, be sure to have it cleaned when using your lights. Whitewash actually blocks a lot of blue wavelengths. This can result in plants stretching more as the red/far-red wavelengths will be more prominent in the greenhouse, activating a stretching and shade avoidance response.

7. Are your capacitors working? If you are still using older magnetic ballast technology, ensure your capacitors are working. If you have bad capacitors, you might experience lighting failure when re-lamping. Since this old magnetic technology is becoming obsolete, replacement capacitors are becoming extremely difficult to find. We strongly recommend upgrading your lighting system to high-efficiency electronic ballast or LEDs.

8. Follow the light plan. To keep your lighting uniform, make sure that your luminaires are installed according to the light plan. Also, make sure the lights are all on the same plane when installing. Having some placed higher and some lower will result in lower light uniformity and can adversely affect plant growth and yields.

It’s important to know that different manufacturers’ luminaires distribute light differently, and a light plan from one manufacturer will differ from the next. You cannot simply swap out one light with another and expect the same results. We recommend always consulting with a professional lighting company to get a plan before any new installations. Always follow the light plan given.

9. Try changing the reflector. Do you want to get more light down deeper in the crop or a wider field of illumination? An easy way to change the distribution of your HIDs is to change the reflector. We offer two kinds of reflectors. The Beta reflector distributes light deeply downward into the canopy and the Alpha reflector distributes light in a wider illumination field.

10. Order early! If you need new lamps or other replacement parts, we recommend ordering as early as possible. This ensures you get the parts when needed and you are not rushing last minute to try and get what you want.