The commercial greenhouse industry has seen significant innovation over the past few years. The greenhouses of today look remarkably different from those considered cutting-edge just a decade ago. The most significant innovations have been in greenhouse technologies—driven by increasing energy and labor costs. Growers have realized the advantages of investing in equipment and automated systems that reduce operating costs (including labor, maintenance, and energy-related costs) and increase their bottom line.

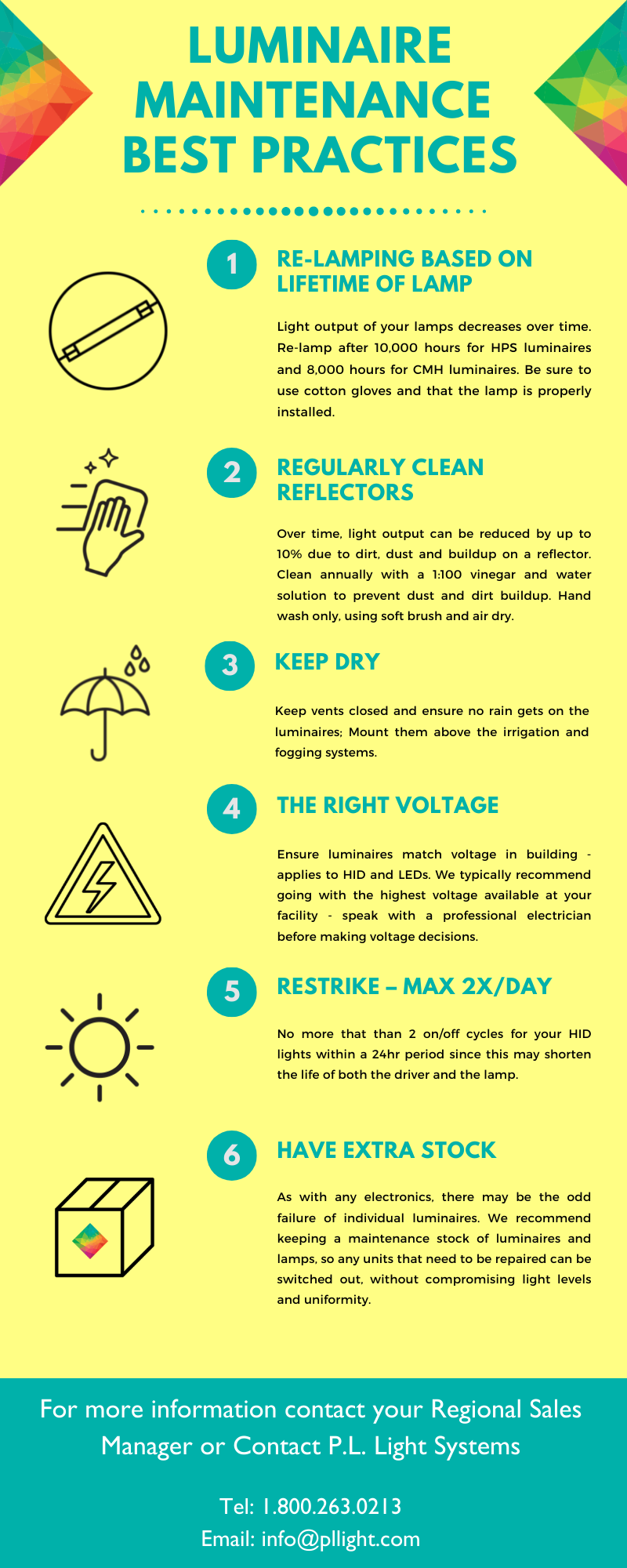

As such, energy-efficient supplemental lighting systems are a logical investment for most greenhouse operators. However, they often don’t realize that, just like any equipment, luminaires need to be regularly maintained to ensure optimal performance.

It’s estimated that light output can be reduced by up to 10% due to dirt, dust, and buildup on a reflector. If not properly cleaned and maintained, this can mean a loss of quality in your crop, longer crop cycles, and reduced yield. To preserve the highest level of performance for your luminaires, we recommend checking and cleaning your reflectors every year if possible. Ideally, this should be part of your cyclical maintenance routine. The process is as easy as removing the reflectors and/or luminaires and washing them in a simple water and vinegar solution. For more information on maintaining your grow lights, check out the P.L. Light Systems maintenance guide